- Home

- Companies

- Metso Outotec

- Services

Metso Outotec services

12 Month Thickener Support Service

Thickeners can present operators with many challenges including those related to process conditions such as changing ore characteristics and increased throughput requirements. Additionally, equipment availability and reliability is paramount so that the thickener role in the plant process does not hinder overall performance. It is therefore vital to take a comprehensive services approach with capable personnel for optimal plant operation with accessible operational support.

Corrective Maintenance Services

Minimize disruption and reduce downtime with our corrective maintenance service for the non-emergency repair or replacement of components that require attention.

Thickening & Clarifying

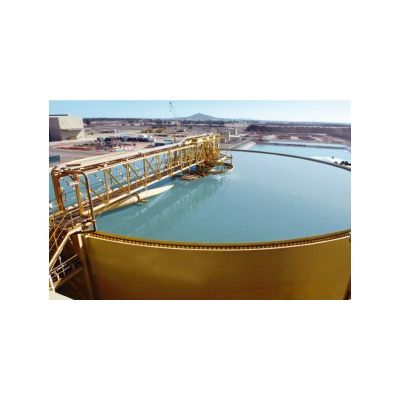

Outotec is a global leader in the design, fabrication and supply of thickening, paste thickening and clarifying solutions to the mineral, chemical and waste water treatment industries. The revolutionary Outotec High Rate Thickener concept has pioneered and redefined the methods of clarification and thickening around the world. With more than 1,400 thickener installations in over 70 countries in the last 20 years alone, Outotec knows how to provide process solutions to enable longer-term cost benefits for thickening and clarification duties and paste applications. Outotec High Rate, High Compression and Paste Thickeners, formerly marketed under Supaflo brand, include a number of innovative features in their design. Special attention is given to the engineering design of feedwells, rake profiles, drive systems and control strategies to meet the challenge of dewatering materials that are often problematic for normal thickeners.

Operations & Maintenance

The reliability of process equipment is only as good as the maintenance it receives. Maximum reliability and efficiency from process equipment can only be achieved in conjunction with an effectively managed maintenance system. Routine maintenance and inspections: The engineers at Outotec’s service centers understand the pressure of process production. Routine maintenance and inspections can reduce the risk of premature equipment failure, breakdowns or poor process performance. These services are essential for ensuring long-term viability and profitability of minerals and metals processing technologies. Outotec services are adapted to fit the customers’ needs. Our service portfolio scales from preventive maintenance inspections to supervision and execution of shutdowns.