MGT Liquid & Process Systems Industries Ltd products

Tanks- Dairy

MGT - Stainless Steel Aseptic Pressure Vessels and Vacuum Tanks

MGT designs and manufactures Stainless steel Aseptic Pressure vessels and Vacuum tanks in a wide range of specifications. MGT Aseptic tanks are built according to ASME Pressure vessels standards and supplied to customers with relevant certifications such as TUV or CE on demand. MGT Aseptic Pressure vessels and Vacuum tanks are designed to withstand cleaning procedures of up to 150°C and subsequently to cool gradually to operating conditions.

Mixers - Mixing Systems

MGT - Vacumm Mixer

Our Vacuum mixer includes a double motion coaxial agitator combined with a high shear rotor-stator homogenizer. The vessel has a double jacket. The system allows a wide range of operation such as emulsion and homogenization, sterilization and other functions under vacuum)or positive pressure. Each drive has independent speed control. Other parameters such as temperature, pH measure, flow, weight and flow control can be regulated easily. Application: Cosmetics and Pharmaceutical, Chemical and Food industry

MGT - Helical Ribbon Agitator

Helical ribbon Agitator with bottom mounted homogenizer (high shear rotor stator type). The helical ribbon agitator combined with homogenizer is a common combination in the cosmetics industry.

MGT - High-Efficiency Double Motion Counter-Rotating Coaxial Mixing Systems

The vessel is designed for high viscosity and semi-solids products with a special agitator configuration that ensures smooth and homogeneous products to improve production time. The vessel is equipped with a top double motion counter-rotating agitator, bottom-mounted high shear homogenizer, and bottom disperser disc to insure excellent homogenization and powder impregnation in the liquid phase.

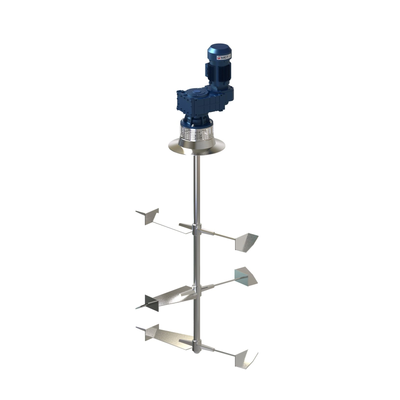

Mixers - Agitators

MGT - Model Mag - Two-Blade, Counter Flow Impeller

Two-blade, counter flow impeller, the MAG impellers have been postulated as very efficient for mixing highly viscous non-Newtonian fluids and is one of the most flexible impeller designs. Intensive mixing of the vessel content and the liquid surface due to a complex up and down movement of the fluid, due to the opposite pitches of the inner an outer blade.

MGT - Helical Ribbon Impellers

Helical ribbon impellers are designed especially axial movement of the liquid (in the process of ‘replacement of liquids’). Such an impeller can be designed with an additional inner helix used to pumping in the opposite direction. This is needed for the mixing of high viscosity materials. These impellers can also have two outer helixes. The quality of the final mixed product in these applications can be very important economically. Wall scrapers can be mounted on the impeller blades to improve heat transfer and homogeneity in sticky products.

MGT - Sawtooth Impellers - Disperser

The Sawtooth impellers is a high-speed disperser disc, which consists as a large number of upward and downward pointing teeth around the disc periphery. A disperser typically used in dispersion applications, e.g. mechanically break up the particles, agglomerates or powders to generate faster and homogeneity distribution or/ and increase the mass transfer / dilution of the solids into the solution. The standard circumferential speed is 15-20 m/sec creates a radial flow pattern together with vortex creation which pump the floating powder into the high shear zone of the blades. The blade surfaces then mechanically tear apart solids thereby reducing their size, and at the same time dispersing them among the liquid used as the solution fluid. The disperser is designed to process a wide range of materials of varying viscosities.

MGT - Hydrofoil Turbine Impellers

Hydrofoils impellers are high efficiency impeller were developed for applications where low shear is important and axial flow is desired. Basically they have two, three or four tapering twisted blades, which are cambered and sometimes manufactured with rounded leading edges. The blade angle at the tip is shallower than at the hub, which causes a nearly constant pitch across the blade length. This produces a more uniform velocity across the entire discharge area.