Microcertec SAS products

Laser and Optoelectronics

Microcertec - Ceramic Optoelectronic Device Components

Ceramic components offer significant advantages over metal and plastic parts. They retain their full dimensional stability at high temperatures – well above 1000°C. They show a high-wear resistance. They are extremely good electrical insulators. They do not outgas in vacuum environment. Ceramics are inert materials and are resistant to many gases and chemicals. The majority of ceramics show high thermal insulating properties but conversly a few of them offer high thermal dissipation.

Microcertec - Heat Sinks for Lasers and Optoelectronic Device

Ceramic components used in laser systems offer significant advantages over metal and polymeric parts in laser systems.

When adequately designed and machined they perform as excellent long-life and reliable heat sinks.

Microcertec - Ceramic Insulators for Laser Systems

Advanced ceramics are widely used in laser systems due to their combined properties of very good electrical insulation - high voltage and high current - and resistance to gas and plasma corrosion. Their resistance to temperature variations, to high temperatures, as well as their very low thermal expansion make them reliable materials to manufacture precision components.

Electronics & Microelectronics

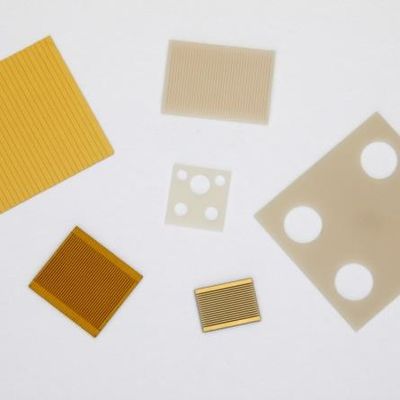

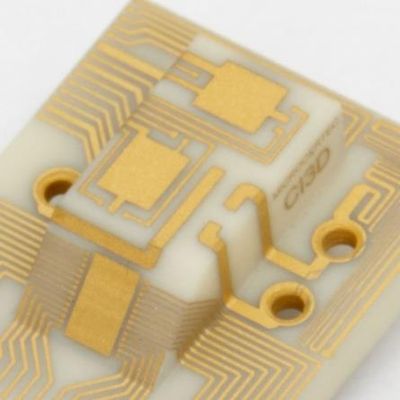

Microcertec - Ceramic Substrates for 3D Interconnection Devices

Microelectronic circuits continuously require new packaging technologies. Ceramic substrates are widely used in this field for their good dimension stability, high electrical insulation as well as their resistance to high temperature. But it is now possible to create microelectronic circuits on 3D carriers made with ceramics. This new type of component integrates electrical and mechanical functions on a same carrier, which gives a wider scope in terms of design and integration. Microcertec has developped a unique expertise to manufacture these ceramic 3D interconnection devices - CI3D - based upon high-precision ceramic grinding of a 3D carrier, thin-film metallizing and laser etching.

Microcertec - Ceramic Components for Microelectronics

Advanced ceramics offer significant advantages over metals and plastics for use in the microelectronics. Ceramics are considered for their high electrical insulation, full dimensional stability at high temperatures, no outgasing in vacuum and UHV environment, and resistance to temperature variations. Finally, the majority of ceramics show high thermal insulating properties but conversly a few of them offer high thermal dissipation. Using vacuum thin-film sputtering technologies, Microcertec can offer ceramic carriers with electrical patterns on which customers will be able to bond or braze. And glass-to-metal and ceramic-to-metal capabilities are also available with Microcertec so that hermetic assemblies such as microelectronic packages and electrcial feedthroughs can be offered to customers.

Hermetic Feedthroughs Assemblies

Microcertec - Glass-to-Metal Seals Connectors

Microcertec offer a variety of leak-tight glass-to-metal seals : single lead or multiple-pin connectors designs which are manufactured by its sister company CTVM. The designs of these assemblies are based on sealing glass and Kovar, molybdenum or stainless steel 316 L metals. They are used in such applications as ignition devices, aerospace and submarine connectors, vacuumm and high-vacuum equipment.