- Home

- Companies

- Microone Co., Ltd.

- Products

Microone Co., Ltd. products

Incinerator Plant

Microone - Medical Waste Incinerator

Jangheung Immediwon Medical Waste Incineration Facility. Medical waste incineration facilities are facilities for collecting and directly incinerating infectious waste from hospitals and medical institutions. Medical waste is a high-temperature combustion gas when incinerated. To address this, the combustion chamber must be designed reliably and the waste gas generated from the incineration of medical waste must be treated efficiently, requiring high technology. MicroOne Co., Ltd. has a lot of experience in facilities, so we will provide better facilities for the stability and durability of incinerators with our own know-how.

Exhaust Processing

Microone - Model SNCR - Selected Non Catalyst Reactor

This is a technology that decomposes and removes nitrogen oxides (NOx) into harmless N2 and H2O by spraying urea water into the secondary combustion chamber through a two-fluid nozzle in the high temperature range of 950?±50?.

Microone - Model SDR - Semi-Dry Reactor

A facility that improves removal efficiency by applying harmful acid gas (HCl, SOx) with a small lime slurry [Ca(OH)] and a second-rate spray nozzle, while preventing waste water from occurring.

Microone - Model SCR - Selected Catalyst Reactor

Most of the nitrogen oxides emitted are in the form of NO and are converted to N2 and H2O by reacting with the reactant while passing through the catalyst at an operating temperature of 200~400?. Here, in this temperature range, the reactant hardly reacts with O2, etc., but reacts selectively with NO, so it is called “selective catalytic reduction”. Ammonia is used as a reactant. Recently, we have developed and applied the SCR technology used at the rear end of the filter dust collector in waste incineration facilities using a low-temperature catalyst. Operating temperature range is 170~200?.

High-Function Filter

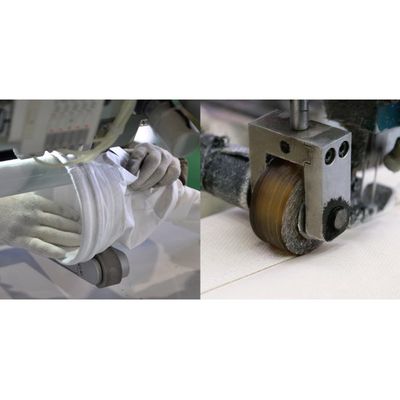

Microone - ePTFE Membrane

Microone’s ePTFE membrane shows high heat resistance of over 250? and is a material with excellent chemical resistance such as acid and alkali resistance, and is produced through a very sophisticated manufacturing process of biaxial stretching. ePTFE me mbrane has excellent dust collection efficiency and high air permeability based on a pore size of 0.5~3.0? and a porosity of over 80%. In addition, it is laminated on the surface of various filter media to prevent dust from penetrating through the filter and dust collection efficiency of more than 99.9%.

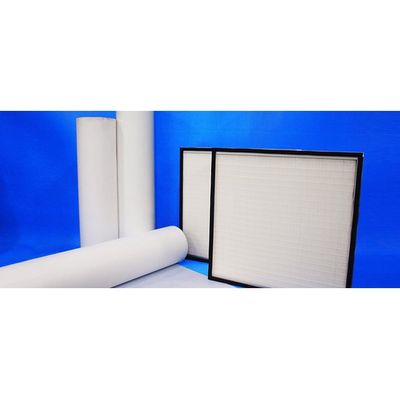

Microone - Model HEPA/ULPA - High-performance Air Filter

HEPA (High Efficiency Particulate Air Filter). HEPA FILTER is a high-performance air filter that captures 99.9% or more of 0.3? particles, mainly used in clean rooms in hospitals and precision processing industries that require high purity. Microone’s HEPA uses ePTFE membrane material developed with its own technology as part of the filter media. Microone’s ePTFE membrane material has superior processability than the widely used glass material, does not generate harmful substances, and has the advantage of saving energy by maintaining low pressure loss.

Microone - Filter Bag

Use of filter dust collector and filter bag. Most common dust collection system among industrial air pollution prevention facilities. Manufacture and supply filter bags of various materials and sizes according to customer’s needs.