Minjie Machinery Co., Ltd

4 products found

Minjie Machinery Co., Ltd products

Vacuum Belt Dryer For Liquid & Paste

Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. Liquid product is conveyed into dryer body by infeed pump, evenly spread on belts by distribution device. Under high vacuum, the boiling point of the liquid is lowered; water in the liquid material is evaporated. Belts move on the heating plates evenly. Steam, hot water, hot oil can be used as heating media. With the moving of the belts, the product goes through from the beginning evaporating, drying, and cooling to discharging in the end. The temperature decreases through this process, and can be adjusted for different products. Special vacuum crusher is equipped at the discharge end to produce different size end product. The dry powder or granule product can be automatically packed or continue with subsequent process.

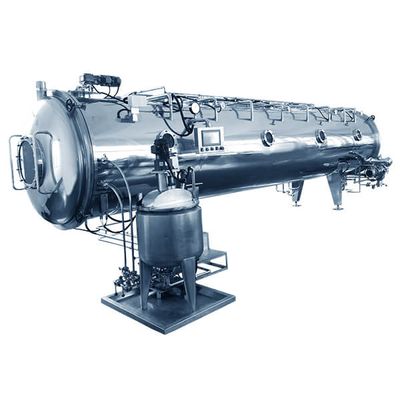

Vacuum Belt Dryer for Powder & Particle

Vacuum belt dryer is continuous infeed and discharge vacuum drying equipment. There are 3-11 layers of conveyor belts inside the cylindrical shell, the more the layers, and the larger the capacity. By feed and distributing device, the wet solid material is input continuously, and then distributed evenly on the conveyor belt under vacuum. Motion of the belt stirs the materials constantly, which speeds up evaporation, thus shortens the drying time, and also makes sure homogeneity during drying. The drying temperature and drying time (from feed-in to discharge) are adjustable(20-150?)(20-80min). If the dried product needs granulation, it can be comminuted under vacuum, no dust flying appears, which increases products’yielding and avoid contamination. The dried product is discharged continuously by vacuum discharging and collecting device. Organic solvent in the wet materials can be recycled by our system, removing pollution problem caused by traditional dryers, and adding profit

Vacuum Low Temperature Evaporator

Vacuum low temperature evaporator is new concentrating equipment developed by our company. It realizes low temperature evaporation through high vacuum degree. There is a spinning roller inside the evaporator. Hot water is used to heat the bottom of the evaporator and the spinning roller. Continuous spinning of the roller increases evaporation area and speed, resulting in thin film evaporation. By continuous contact with the surface of the spinning roller, the raw thin material is heated to evaporate. From feed to discharge, the whole concentration process is continuous under vacuum state. Vacuum low temperature evaporator conquers many problems met by traditional evaporator, such as, high concentrating temperature, long concentrating time, denaturation of raw material, easy scale formation during concentration, poor fluidity after concentration and no further concentration. Because of the low evaporation temperature in our equipment, active ingredients of the raw material are kept.

Thin-Layer Drying System

Thin-layer drying system is a new-style low temperature drying equipment which developed by Shanghai Minjie. It adopts low temperature radiation & thin layer drying technology which is called “the fourth generation drying technology” by international drying academic world. Equipment has “high efficiency, high quality, low energy consumption” features. Thin-layer drying system consist of feed and distributing system, heating and drying system, low temperature air exhausting system, cooling system and discharging system, and the composition principle is shown in the figure.