- Home

- Companies

- Mokesys AG

- Products

Mokesys AG products

Rear-Ventilated

Mokesys Air - Model 2E - Rear-Ventilated Tiling Systems

The rear-ventilated tiling systems offer effective protection from corrosion due to the circulating air behind the tiles. The heat extraction can therefore be individually tailored by adjusting the stud fixings. The Mokesys® Air 2E is used in the first boiler pass. It comprises nitride bonded SiC tiles and a layer of constantly circulating air which is created by an external supply system. The newly developed Mokesys® Air UHS, for which a patent is pending, offers permanent protection for superheater bulkheads in the second pass. Small amounts of air are blown, at low pressure, between the superheater’s tubes and the Mokesys® Air UHS tiles. The circulating air provides ideal protection against corrosive flue gases.

Mokesys Air - Model UHS - Rear-Ventilated Tiling System

Alongside the existing Mokesys® Air system, which is used in the first pass, the new Mokesys® Air UHS offers long-term protection for superheaters in the second pass. As with all Mokesys® tube wall protection systems, this one also comprises premium-quality SiC tiles and their fixings. It is ingeniously simple to operate: at low pressure, small quantities of air are blown in between the superheater tube wall and the Mokesys® Air UHS tiles. The air which thus circulates affords optimal protection against corrosion. A further major advantage is that Mokesys® Air UHS tiles can be installed easily and quickly, thus saving valuable time during construction or dismantling in comparison with conventional methods of protection for superheaters. The result is a customised refractory lining which retains a high degree of flexibility over a long period of time and thus significantly extends the system’s disruption-free operation.

Back-Cast

Back-Cast Mokesys - Model Standard - Double Protection Against Tube Wall Corrosion

A proven solution for 18 years and still as effective as on day one – the Mokesys® Standard system safeguards against tube wall corrosion in two ways: first with a thin, sealed layer of specially developed low porosity, fine-grained SiC castable concrete; and second with internationally patented Mokesys® tiles. Together these two elements afford double protection. The nitride bonding of the fine SiC granules and the double firing of the tiles result in sustained service life because they can cope with aggressive slag attack, high temperatures and high rates of energy density, whilst providing superior resistance to oxidation and thermal shock. The tile dimensions can be tailored to suit your needs and are entirely modular. Thanks to the direct link between the refractory lining and the boiler tube wall, this Mokesys® system achieves a high degree of heat recovery.

Back-Cast Mokesys - Model Standard Plus - Double Protection Against Tube Wall Corrosion

The enhanced, refined variant of the proven Mokesys® Standard system. The dual protection against tube wall corrosion and the extraordinary oxidation and thermal shock resistance properties, as well as the high degree of heat transfer, have naturally been retained. Over and above this, Mokesys® Standard Plus now provides the balanced accommodation of expansion forces by means of its suspension from lower and upper support brackets. Thus, opposing tension and compression forces can be excellently coped with in critical, high-demand zones. A further advantage of this system is that it has 50% fewer tile joints, yet is more flexible and manoeuvrable.

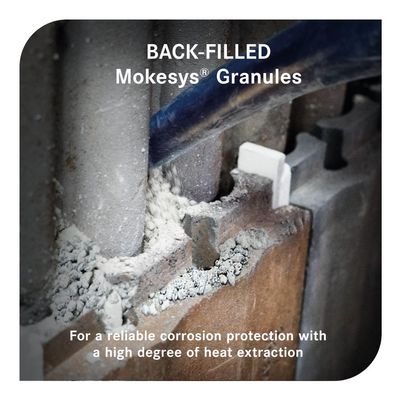

Back-Filled

Back-Filled Mokesys - Granules

In recent years, Mokesa AG has added another innovative product to its range. Now, Mokesys® can also be backfilled using refractory granules. A granular fill, specifically developed for this purpose, incorporates a special binder to ensure lasting integrity. Our Mokesys® granules are versatile in use and offer numerous advantages over conventional systems. On the one hand, the support brackets are still enveloped in clean air for reliable corrosion protection and on the other, the granular fill results in improved heat recovery. The granular system also facilitates simple, swift and secure disassembly.