Mono products

EZstrip Family

EZstrip - Progressing Cavity Transfer Pump

For the newest iteration of our EZstrip™ maintain-in-place progressing cavity pump we designed new features to make maintenance even more user friendly than before. In addition to our patented split suction chamber we’ve removed the tie bars, designed a new positive torque split coupling rod, and added in a captive support foot. That means faster, easier maintenance for you. The EZstrip has been specifically designed to provide a quick and easy way to disassemble, de-rag and maintain a PC pump in-situ, eliminating the costly maintenance and down time that servicing can often cause.

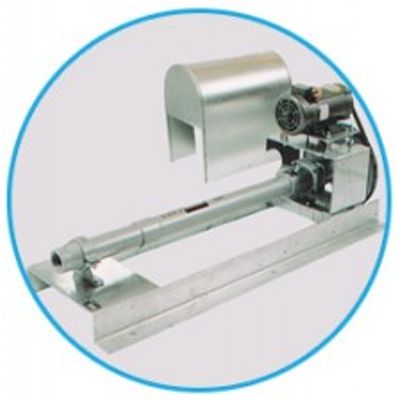

EZstrip - Progressing Cavity Cake Pump

Following the successful launch of the revolutionary EZstrip progressing cavity pump, Mono has developed the EZstrip Cake Pump to make the process of maintaining a cake pump easy. The EZstrip cake pump features a specially designed feed chamber which is easily disconnected allowing access to the rotor and screw conveyor assembly. The rotor can then be separated from the conveyor allowing removal of the rotor and stator while in-situ, without disconnecting suction and delivery pipework. This process can take as little as 6 minutes. Imagine the time savings you could achieve when maintaining an EZstrip cake pump!

Solar Products

Model Sun-Ray SRX - Solar-Powered Water Pump

The Mono Pumps Sun-Ray SRX solar pump has been designed to transfer surface water with the same efficiency and reliability as other Mono solar pumps. Available, with either a stationary or GPS Tracking array, ranging from 175 Watts to 1400 Watts, the Sun-Ray can deliver very high daily flows with discharge pressures of 120m.

Packaged Systems

Model Discam - Wastewater Grinder and Screen

The Discam is a unique new grinder and screen package, which offers a much more effective and low maintenance alternative to handling screenings than conventional systems. With the ability to capture up to 95% of solids at 5mm or 9mm aperture sizes, this innovative solution combines the self-cleaning Discreen with a high torque Muncher. No manual attendance or cleaning is required and disposal costs for handling debris extracted by traditional screening processes is eliminated. The Discam is constructed using a series of shafts, two of which are fitted with interleaving cutters and spacers to give ‘positive displacement’ solids grinding, whilst the remaining shafts are fitted with overlapping and intermeshing discs. Easily retrofitted into existing sewage pump stations or inlet works, as well as installed in new build facilities, this high performance package is suitable for almost any type of waste water facility.