Monroe Environmental Corporation products

Air Pollution Control Systems & Equipment

Monroe - Packed Bed Wet Scrubbers

Monroe Environmental is a single source solution for highly durable and efficient Packed Bed Wet Scrubbers. A Packed Bed Scrubber is a wet air scrubber that removes acids, soluble gasses, chemicals, fumes, and odors. Contaminated gas flows through a specially designed packing media that is wetted with recirculated liquid. The liquid solvent absorbs the gas pollutant by physical or chemical means. A blowdown from the tank with makeup water addition removes contaminant products before they precipitate.

Monroe - Venturi Wet Particulate Scrubbers

Monroe Venturi Scrubbers are wet particulate dust scrubbers designed to remove both heavy and light airborne particulate matter from exhaust systems, as well as flue and process gasses. Venturi Scrubbers bring particulate-laden air streams together with water at high velocities to transfer the particulate into the water stream. The water droplets and particulates are then removed from the air stream through centrifugal separation and mist elimination stages.

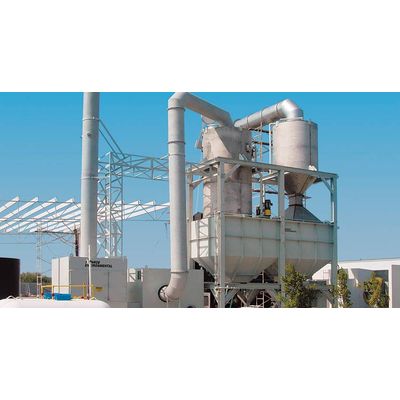

Monroe - Multi-Stage Air Scrubbing Systems

Monroe Environmental can provide complete multi-stage air scrubbing systems for a wide variety of applications. High temperature and volatile chemical processes often require a more complex, customized air scrubbing solution than what a simple packed tower scrubber or venturi particulate scrubber can provide.

Monroe - Quench Towers and Condensers

Monroe Environmental Quench Towers and Condensers provide temperature reduction and control of hot process gasses through evaporative cooling, condensing, and a variety of heat transfer methods. A Quench Tower or Condenser is often the first step in conditioning a high temperature, polluted air stream so that particulate, acid gasses, metals, and other emissions can be adequately removed. Quench Towers and Condensers are often used following thermal treatment systems such as incinerators, reactors, kilns, boilers, furnaces, oxidizers, and other process systems that produce contaminated gas streams at elevated temperatures.

Monroe - Wet Electrostatic Precipitators (WESPs)

The Monroe Wet Electrostatic Precipitator (WESP) provides high efficiency collection of PM2.5, submicron, and fine particulate matter. Monroe Wet ESPs are designed to achieve very low PM emissions with reliable operation and minimal maintenance.

Monroe - Cartridge Dust Collectors System

High performance industrial dust collection systems for dry dust and MQL applications. Continuous collection and removal of airborne dry dust and particulate matter (PM) with reverse pulse cleaning of bags or cartridges allows operation without shutdown.

Air Pollution Control Systems & Equipment - Monroe Oil Mist Collectors

Monroe - Multi-Stage Oil Mist Collectors

Provides more filter media, longer operating time between filter changes, and higher collection efficiency. The Monroe Multi-Stage Oil Mist Collector is designed to collect and remove airborne oil mist, smoke, and submicron vapors generated by operations such as high production machining and cold forming. It is a multiple stage collector that has proven capabilities exceeding 99% efficiency on many installations.

Monroe - Fiber Bed Oil Mist Collectors

Ideally suited for removing submicron aerosols and mists with high efficiency coalescing filters. The Monroe Fiber Bed Mist Collector is a custom designed unit consisting of a continuous-duty, aerosol coalescing filter and integral fan assembly. Mist is collected using filter elements consisting of micro-fine fiberglass or synthetic fibers. This compacted media is in the form of cylindrical units. These long-life filters can provide several years of service before replacement is necessary. When the mist contains heavy droplets and/or dust particles, pre-filtering is provided by separate filter screens. Efficiencies of 99.5% on 0.3 micron mists are typical.

Air Pollution Control Systems & Equipment - Monroe Compact Mist Collectors

Monroe CMC - Multiple Stage Mist Collector

The CMC Mist Collector is capable of removing airborne mist and submicron vapors generated by high production machining, cold forming, and a wide variety of related applications. It is a multiple stage collector that has capabilities to exceed 99% efficiency, while minimizing the maintenance requirements and floor space issues of competitive mist collector designs. The installation of a Monroe CMC Mist Collector allows you to discharge clean, filtered air back into the work area, reducing climate control costs and improving worker safety.