Neuman & Esser (NEA Group) products

Compressors - Compressor Systems

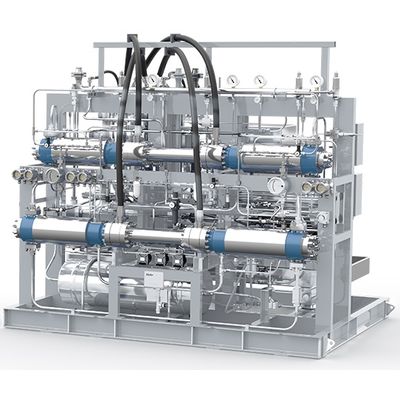

Professional Compressor Unit System

Qualified employees and an innovative corporate culture enable NEUMAN & ESSER to implement the requirements and specifications on the customer’s side in efficient production systems within the shortest time. NEUMAN & ESSER plant engineering already takes all the concerns occurring throughout the compressor unit’s life cycle into account when preparing its technical design and planning the construction of its components. NEA is specialized in realizing unusual applications, meaning that, in particular, customers with complex requirements are in good hands here.

Customer Compressor Unit system

NEUMAN & ESSER impresses customers with an innovative Product Life Cycle Management Concept (PLM). Here, the link between the CAD and ERP (SAP) systems is almost revolutionary. The major benefit is the homogeneous structure, which starts during the sales phase and covers all aspects of customer requirements up until commissioning and operator training. The exchange of 3D data in the common formats is equally part of this concept as is the very early availability of, for example, the coordinates of transit stations and building concept details.

The customer-specific system is developed in close collaboration with the customer. Unique within the market, the 3D depictions of the system comprise one of the core tools for collaboration with the customers.

Compressors - Revamp & Modernization

Reciprocating Compressors and Diaphragm Compressors

Revamping and modernization offers the possibility to adapt existing reciprocating and diaphragm compressors to changed operating conditions and to improve immobilization as well as availability, because in most cases it is less expensive to revamp compressors than to purchase a new system. For this purpose, NEUMAN & ESSER implements engineering and creates a schedule of specifications for the optimum performance of existing compressors and system components in accordance with the current requirements specifications.

Reciprocating compressors

Reciprocating compressors are tailor-made machines which are designed for the defined operating conditions. Adaptation of the compressor output and changed parameters are the most frequent reasons for revamping and modernization measures. Customers also often decide to modernize their existing system in order to achieve technical improvements or modern, energy-efficient control systems.

Compressors - Hydrogen Compressors

Model TKH - Hydraulic Driven Dry Running Piston Compressors

Compression of small amounts of hydrogen using dry running piston compressors. For such volatile operating scenarios hydraulic driven dry running piston compressors (TKH) also from Andreas Hofer can be a viable alternative. The TKH is also able to reach very high pressures of up to 3,000 bar (45,000 PSI) and it also offers oil-, leakage and technically abrasion free compression. The number of strokes per minute can be easily controlled via the hydraulic control unit, this ensures an efficient capacity control. For small volume flows and high pressures, as e.g. required for light vehicle fuel stations, the TKH is the compressor of choice.

Process - Mills

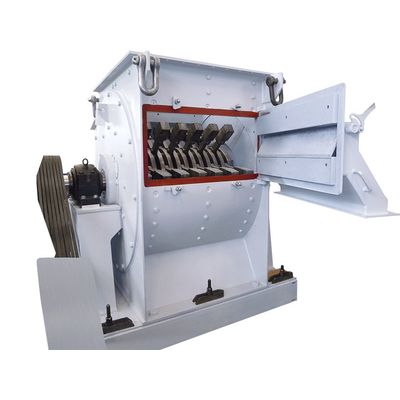

Robust Hammer Mill

The hammer mill, also known as the Pulverizer, works according to the principle of impact grinding. Its core consists of a rotor with wear resistant impact hammers and external housing for the roller bearing. The NEA hammer mill HM is highly suitable for grinding soft to medium-hard materials such as minerals, hydrated lime, bauxite and plaster.

Process - Classifier

Model NEA GRC - Guide Ring Classifier

The GRC guide ring classifier from NEUMAN & ESSER is a latest generation high-efficiency air separator, which offers top yields, precise separation limits and minimum energy requirements. It can be operated as an independent aggregate and combined with a mill. The feed material is fed from the top using a vertical pipe. After the feed material drops into the dispersion unit, it enters the classification zone. The air required for classification carries the particles to the classifier wheel. Small particles, the fine materials, are being pulled through the classifier wheel by the classifying air. The fine material is then separated from the air in the following filter. The classifier wheel rejects particles which are too large and they reach the bottom of the classifier as coarse material. An airlock discharges this material there.

Process - Filter

NEA - Cyclone Cartridge Filter

All NEA grinding and classifying systems, but also several other technical process systems such as pneumatic conveyor devices, driers and others work with a solids-laden air or gas flow. Filters separate solids from process gas as powders, enabling feeding to further processing. NEA filters are available for high requirements pertaining to air quantities, dust load and residual dust content and are characterized by a long working life with constant separation quality and low pressure loss. NEUMAN & ESSER also provides solutions for difficult products such as fine and adhesive products which tend to get stuck and are difficult to run off.