Newman Machine Company, Inc. products

Cutterhead Grinders

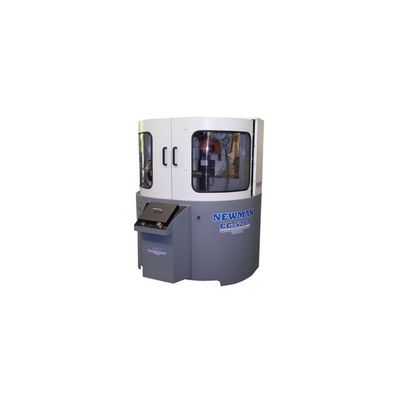

Newman - Model CG-520A - Fully Automatic Universal Cutterhead Grinder

From the construction of the enclosure, heavy duty bearing rails for the sliding doors to the servo drive components, the CG-520A is built to provide quality grinding of all your cutterhead requirements in the most demanding environments.

Newman - Model G-716 - Semi-Automatic Cutterhead Grinder

The G-716 Semi-automatic Cutterhead Grinder is used to sharpen 7” to 16” diameter eased edge, milled to pattern, and fingerjoint cutterheads. Worktable traversing is automatic and has adjustable stops. Cutterhead indexing is manual. Each knife is held against a positive stop while being ground.

Newman - Model G-716A - Fully Automatic Cutterhead Grinder

No index plate to change when working with heads with different numbers of knives. The use of an index plate assumes that the knives and head separations are uniform throughout, which is often not the case. If the height of the knife is high or low, then the front face of the knife will vary from knife to knife making the task of grinding difficult. The one constant is the back face of the knife, therefore the use of an indexing stop against the back face will provide for accurate indexing regardless of the irregularities in the knives and head slots.

Planer-Matcher Systems

Newman - Model FT-1600 - Feed Table

The FT-1600 Feed Table is designed to ensure that a continuous ribbon of lumber is available to the planer. The machine frame consists of structural steel providing maximum rigidity. The feed works include two pineapple rolls and one top outfeed roll. Each is driven by an individual electric motor. The pineapple rolls may be quickly raised and lowered to feed thick or thin lumber through the use of jam clearing controls furnished as standard equipment.

Newman - Model PB-1600 - Powered Bridge

The powered bridge facilitates high speed butt feeding so that an uninterrupted ribbon of lumber is presented to the planer for maximum production. The heavy duty frame contains 16” feed rolls mounted in pillow block bearings. The PB-1600 has electric feed drive and is V belt driven with a 25 hp motor.

Sanders

Newman - Model A-4000 - Widebelt Sander

The Newman A4000 Series Widebelt Sander has been designed to provide increased production volume and increased width requirements in heavy workload environments. Solid steel plate weldments and modular design are trademarks of Newman quality woodworking machinery. The A4000 Series has been designed and built in America for the American market. Designed to be the heaviest in the industry, the A4000 Series will provide tight tolerance work and high quality surface finish for all of your tough abrasive finishing requirements.

Specialty Planers

Newman - Model LB-855 (S2S Version or S4S Version) - Wide Bed Surfacer

The LB-855 Wide Bed Surfacer provides our customers with the ability to surface wide materials top and bottom up to 55″ in width and 8″ in height. It is an excellent choice for glu-lam, particleboard and other composite materials. For glu-lam customers the LB-855 may be equipped with the optional sidehead and outfeed roll units allowing beams to be surfaced and eased-edged in one pass. It can be equipped with a “floating side head” which can accommodate up to 8″ of camber. Equipped with the Newman Helical Carbide Cutterheads and powered by 100 HP coupled 1800 RPM motors, the LB-855 provides for the quiet, low-vibration, high performance operation necessary in today’s world market.

Others

Newman - Helical Carbide Cutterhead

The Newman Helical Carbide Cutterhead provides significant improvements over conventional cutterheads in terms of noise, cost, and performance. The Challenger Award winning cutterhead has become the industry standard. Replaceable carbide tipped cutters fit precisely into the helical slot to form a continuous helical cutting edge providing the most technologically advanced cutting action available. Newman Helical Carbide Cutterheads are being used extensively in the woodworking and plastics industries throughout the world with applications including finish planers, roughing planers and high- speed planer-matchers.

S-382 Retro Fits

Air Operated Pressure Bar

The air operated pressure bar release enables the operator to clear jams from the maintenance console as well as the remote pedestal console which is located at the operators control station. Rather than having to leave the main control panel to manually release the pressure bar, clearing a jam can be as simple as pushing a button. The air operated pressure bar is easy to install and will make your operation more efficient.

Anti-Kickback Fingers

Anti-kickback fingers are required when hand feeding the machine. Unit is equipped with an air quick release when reverse is selected.