NHE products

Surface Treatment

NHE FPI - Fully Automated Surface Treatment Systems

Our fully automated surface treatment process lines utilise the latest computer hardware and Plasticraft software to maximise process and handling efficiency, and can be configured to meet NADCAP requirements. As a result, high levels of consistency are achieved with optimum manpower utilisation, traceability and the provision of management systems data. Overall Equipment Effectiveness (OEE) measurement can be achieved by the continuous monitoring of plant and processes via a real-time link to our head office in the UK.

NHE FPI - Manual Plating and Surface Treatment Systems

Manual plating and surface treatment facilities complement automatic lines and gain from the same experience and design team focus. Processing expectations are achieved via a commitment to build quality, on-time delivery and value for money with operating efficiency, safety, versatility and ease of maintenance prime priorities for every installation.

NHE FPI - Encapsulated Plating Systems

Our expertise in automated plating lines extends to the design and manufacture of Encapsulated Plating Systems for a range of plating processes. Systems are custom designed and can include integrated wastewater treatment plant.

NHE FPI - Fume Extraction and Abatement Systems

NHE design and manufacture a comprehensive range of fume extraction and abatement systems and equipment to achieve long term operating requirements and COSHH obligations in the finishing industry. Systems range from vertical packed bed fume scrubbing towers, chrome mist elimination systems and horizontal wet fume scrubbers to chemical resistant fans, air replacement facilities and exhaust systems manufactured in a choice of materials.

Non-Destructive Testing

NHE FPI - Automated Non-Destructive Testing Systems

FPI Engineering automated non-destructive testing systems satisfy the requirements of high volume workflows. Excellent process control and consistency is achieved by automating the testing systems which can also be equipped with data logging technology for monitoring in accordance with NADCAP requirements.

NHE FPI - Manual Non-Destructive Testing Systems

FPI Engineering manual non-destructive testing systems are highly versatile and cost effective, combining simplicity of operation with the ability to accommodate a wide range of component sizes. Our manual non-destructive testing systems offer you an ideal solution for situations where space is restricted yet testing is a vital part of your production chain.

NHE FPI - Non-Destructive Testing Booth Systems

FPI Engineering non-destructive testing Booth Systems offer you maximum versatility in terms of process and plant layout.

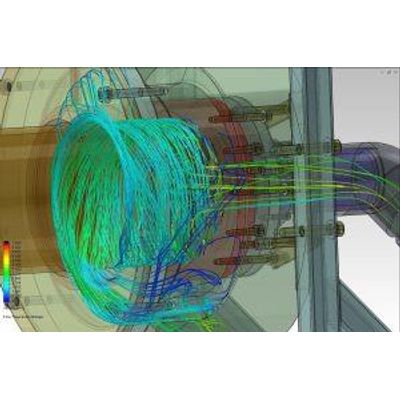

NHE FPI - Non-Destructive Testing Carousel System

The NHE non-destructive testing carousel system is a space-saving, fully enclosed design that enables simultaneous processing for large volume inspection and production. The fully-automatic carousel system provides fluorescent penetrant inspection processing in a choice of configurations and sizes.

Process Water Recycling

NHE FPI - Filtration Systems

Lancy Technology utilises the advantages of different membrane materials and available pore sizes to achieve a maximum of process performance and reliability. Our membrane systems utilise cross flow filtration in which the flow of contaminated liquid is parallel to the membrane surface. This allows the clean water phase (permeate) to pass through the membrane while minimising fouling of the membrane surface.

NHE FPI - Wastewater Treatment Metal Recovery System

Many industrial wastewaters contain dissolved metals as a result of their manufacturing processes. Wastewater treatment metal recovery systems are designed to reduce metal contaminants, such as mercury, lead, cadmium, silver, copper and chromium, to meet discharge requirements and/or achieve the water quality level needed for reuse and recycling.