- Home

- Companies

- Noardling B.V.

- Products

Noardling B.V. products

Noardling Hubert - Micro Screen

A Hubert micro screen is applied in places where high demands are made on the purity of surface, process and re-circulated water. Hubert micro screen or microstrainer can be found in freshwater intakes, acting as fine pre-flit ration system of potable water for production plants, or production plants that consume a lot of processwater. This filter can also be applied for process water recirculation. The recovery of useful raw materials from process water, stricter discharge requirements, and recycling of process water makes the use of these engineered filters increasingly interesting. Other applications are treatment of effluent in a wastewater treatment plant and pre-flltratton in membrane filtration systems.

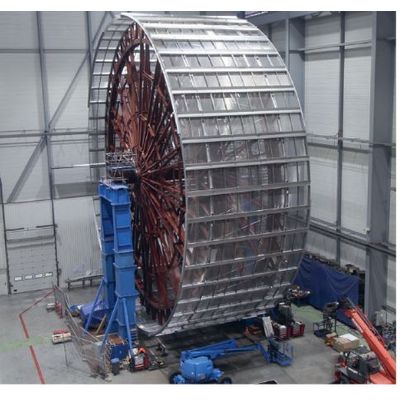

Noardling Hubert - Vertical Drum Screen

A Hubert vertical drum screen - the `heart` of a `screening train`. A drum screen is typically installed in water intake systems downstream from coarse bar screens. Regularly occurring fow rates are between 40.000 and 120.000 m3/h per screen, depending on customer requirements and the local situation at the intake. A drum screen is used for relative fine filtration; the filter medium is a woven mesh with a wire diameter of about 2-3 mm.

Noardling Desah - Sanitation System

For the Desah new sanitation system, domestic/ residential wastewater/sewage is separated at the source into grey and black domestic wastewater and rainwater streams. Grey and black water remain separate throughout the process and are transported to a compact decentral treatment facility in the neighborhood. After the treatment the water can be reused or released to surface water.

Noardling Desah - Decentralised Wastewater Treatment Plant

Desah designs, constructs, implements and operates decentralised wastewater treatment systems for domestic wastewater, all of which are modular and flexible.

Noardling Hubert - Water Intake System for Industrial and Power Plants

Hubert water intake systems are used to mechanically clean or screen water extracted from the sea, rivers or lakes. Mechanical cleaning removes unwanted matter with screens or sieves. This protects the downstream process stages from build-up, clogging and abrasion. The aim is to protect suction pumps and other downstreamequipment such as desalination membranes, heat exchangers/ condenser tubes from the carry-over of coarse and fine debris.

Noardling Hubert - Model DAMRAN - Cable Operated Bar Coarse Screen

The cable-operated DAMRAN machine is used particularly for removing medium- and large-scale coarse debris from a water inlet. This highly reliable machine can be used independently or in series, side by side.

Noardling Hubert - Static Coarse Screen

A coarse bar screen is exposed to significant forces and is therefore engineered specifically for your project application. Its design is simple, robust, and highly functional, ensuring optimal cleaning performance. The Hubert static bar screen can be equipped with raking systems for efficient debris removal. Additionally, multiple static bar screens can be used in combination with the Hubert trash rake gripper for enhanced cleaning capacity.

Noardling Hubert - Travelling Band Screen

A Hubert travelling band screen is the `heart` of the `screening train`, often used used for (sea)water intakes as part of power plants and desalination plants, where big tidal differences can also play a role. It is more compact than a (vertical) drum screen, but it has still a high capacity. Quite common flow rates are 15.000 m3/h per screen, depending on customer requirements and the local situation at the intake. A travelling band screen is typically installed in water intake systems downstream from coarse bar screens. Woven mesh with a diameter of approx. 2-10 mm is used as relative fine filter medium.

Noardling Hubert - Trash Rake Gripper

The Hubert automated cable-operated trash rake gripper (also known as a screen cleaner) is designed for versatile use. It can be installed in front of multiple static bar screens or racks to directly remove debris from incoming flows. Additionally, it can be positioned behind multiple Hubert DAMRAN units to handle locally collected debris. A wide range of configurations is available to suit your specific project requirements and preferences. The overhead gantry, monorail, and portal are constructed from high-quality, heavy-duty steel. The drive track is located approximately 4.5 meters above the deck.

Noardling Hubert - Model WISA - Revolving Coarse Bar Screen for Medium Flows

The Hubert mechanical raked barscreen, type WISA, is designed for automatically pre-cleaning of surface- or waste water influent from small and medium-sized channels. The WISA is ideal for removing large quantities of debris in a short time. The screen is executed in front-raked operation. A chain operated coarse screen is also called a revolving bar screen or revolving chain screen. The design is simple, robust and functional with a maximum cleaning result.