Novotec N.V products

Pre-Treatment

Novotec - Screw Conveyors

Pretreatment systems are especially designed to withhold coarse materials from waste water flows. The separated material has to be collected in a functional way in order to keep operational costs at a minimum. Novotec offers a wide range of conveyor screws capable of getting the materials where they need to be. Whether it is sludge, gravel, sand, debris,… the right conveyer screw will transfer it to the ideal storage place. Novotec can offer single drop point systems or automated distribution systems filling containers at several drop points. Even pivoting screws are part of our product range.

Novotec - Sand Separator

The Novotec NSP type sand separator sets gravity to work for your benefit. This reliable pretreatment system is perfect for separating particles with a density higher than water from waste water streams. Designed to trap quick settling particles such as sand, gravel, stones or dirt from water. The system consists of a holding vessel allowing the particles to settle, while the cleared water is discharged. An additional Archimedes screw extracts the settled particles continuously, thus making it a self-cleaning system capable of working without interruption.

Novotec - Lamella Separator

Novotec designs and produces lamella separators, adapted to treat a wide range of waste waters. This unit consists of a clarifying tank fitted with lamella packages. Lamella separators are more compact, compared to a settler with the same capacity. It is intended to separate solids with a higher density than water. By creating laminar flow through the lamella packages, the solids are separated at a high efficiency without the need of a large ground surface area. The unit has no moving parts and works solely on the principle of separation by gravity. By fitting settling cones on the bottom, the separated sludge is collected. By means of pneumatic valves, the sludge is extracted from the sludge cones . In case the waste water contains both settling and floating matter, the lamella separator can be fitted with an optional scraper system – allowing the floating layer to be removed continuously.

Physical-Chemical Treatment

Novotec - Stirring Flocculator

Stirring flocculators are used in chemical treatment systems where longer contact between the medium to be treated and the chemicals is required. The NRF units, made of chemical resistant plastics, such as polyethylene or stainless steel, offer optimal user friendliness. Thanks to its optimized internal layout and suitable stirring unit, we assure that all of the water flow comes equally in contact with the dosed chemicals. The unit is adapted to the intended use of chemicals and the physical properties of the flocs to be formed. Attention to the internal layout, assures that all of the water flow has been equally in contact with the dosed chemical. Additional features such as pH-probes, chemical injection points, level detection devices can be installed for easy integration in the waste water treatment installation.

Novotec - Polymer Preparation Unit

Novotec offers a wide range of polymer preparation units. All these units are intended to dilute a concentrated polymer powder or liquid polymer to a known concentration, ready to be used in a physical chemical treatment process or sludge dewatering system.

Novotec - Pipe Flocculator

The NPF pipe flocculator designed by Novotec is a mixing device used to inject chemicals in a waste water flow. The highly effective design includes pipe diameter changes and numerous bends, creating a turbulent water flow with excellent mixing properties. This avoids the need for additional energy input in order to get a good chemical reaction. The standard NPF unit, constructed in chemical resistant Polyethylene, is fitted with the chemical dosing points, sample valves, drain valve and features a flanged design – making it easy to disassemble the unit for cleaning purposes. Optional features such as retractable pH-probes and aeration points, create a device perfectly suited for use in physical-chemical treatment systems. Coagulation, flocculation and pH correction are achieved in one single unit.

Biological Treatment

Novotec - Submerged Aerated Fixed Bed Reactor (SAF)

The Biofix system engineered by Novotec features aerated fixed bed technology. A carrier material is fitted into a bioreactor. The unit includes an aeration grid with external blower. Biomass accumulates on the carrier and treats the waste water which passes by. By dividing the reactor into different compartments, specific biology develops in each section. This phenomenon causes an environment where the excess biological sludge is degraded inside the bioreactor, resulting in a minimal sludge production.

Novotec - Sequenching Batch Reactor (SBR)

The SBR reactors engineered by Novotec offer high treatment efficiency combined with a reduced footprint. Classic continuous waste water treatment plants consist out of a pretreatment, biological reactor and sludge settling tank. The SBR system combines the last two steps in one tank. By working in batches, the waste water can be treated in this single reactor. The reactor is filled with a fixed volume. Next, the reactor is aerated – ensuring optimal mixing and contact time of the biology and the waste water. When the treatment cycle has ended, the aeration is stopped and the biological sludge settles on the bottom of the tank. The upper clean water layer is finally pumped out of the reactor and the system prepares to treat a new batch of waste water.

Novotec - Moving Bed Bio Reactor (MBBR)

The Novotec MBBR reactor combines the advantages of the classic active sludge and fixed bed biology. The reactor is filled with floating carrier materials called chips with a high specific surface. These chips allow to grow a highly concentrated microbiology, while keeping them in constant movement. The installed aeration supplies the needed oxygen for the biology and simultaneously mixes the content of the reactor.

Sludge Management

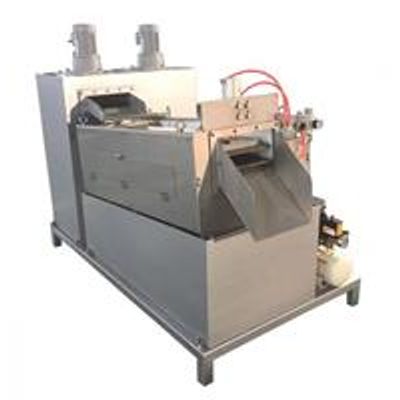

Tumbl - Sludge Management Pilot Unit

The Tumbl-R unit offered by Novotec is perfectly adapted to treat difficult sludges. Engineered as a stand-alone, self-cleaning dewatering system, it is a perfect alternative to classic dewatering techniques. Sludge is transported over a stationary filter plate, by rotating oval discs. The longer the sludge travels over the filter plate, the more water is separated from the sludge. The rotating oval disks do not only transport the sludge, they but also keep the filter plate free from clogging. An optional, adjustable endplate regulates the pressure on the sludge and obtains the optimal sludge cake dry matter content.