Oberländer Recycling Machines GmbH products

ORM - Stationary Scrap Shears

Oberländer Recycling Maschinen GmbH presents their stationary scrap shears, designed specifically for the efficient processing of heavy scrap materials like construction scrap and rebar bales. These press shears, bolstered by over 50 years of engineering experience, leverage a distinctive shear slider guide system supported by columns, ensuring minimal contact with scrap and contaminants. This unique design drastically reduces wear, maintaining precise cutting tolerances without necessitating regular adjustments. Constructed as torsion-resistant welded heavy units, these shears forego anchoring, curbing foundation costs. Innovations in this latest generation include easily maintainable cylinders, faster cycle times courtesy of advanced hydraulic control, and enhanced energy efficiency with power-controlled double pumps. With features like an air-conditioned control cabin, effective central lubrication, and a pre-filling trough for simultaneous loading and operation, these shears promise reduced maintenance, increased productivity, and seamless operation even under demanding conditions.

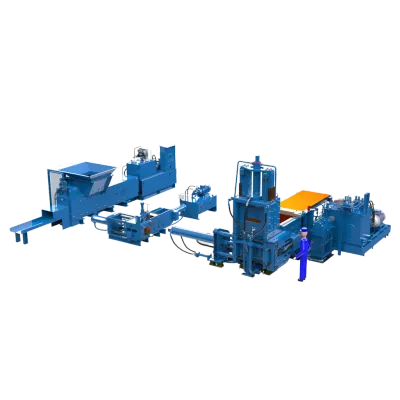

ORM - Scrap Baling Presses

Oberländer offers a comprehensive range of scrap baling presses designed for efficient scrap bundle production across various industries. These presses range from basic two-compressor models suitable for thin-walled production waste, such as cans, to advanced multiple-compressor systems with hinged lids for handling bulky mixed scrap. The baling presses are highly adaptable and can be integrated directly into production lines to compress scrap on-site, minimizing volume. Their resilience and effective compaction make them suitable for standalone use in recycling yards or integrated usage in industries like automotive, sheet metal processing, and non-ferrous metal processing. Apart from compaction, these systems are equipped with advanced automation features such as loading units, conveyors, and handling systems that facilitate efficient pallet or container stacking. Oberländer's solutions emphasize automation to enhance operational efficiency and reduce costs for industrial recycling applications. The high pressing force ensures the creation of uniform, durable bales capable of withstanding rigorous handling.

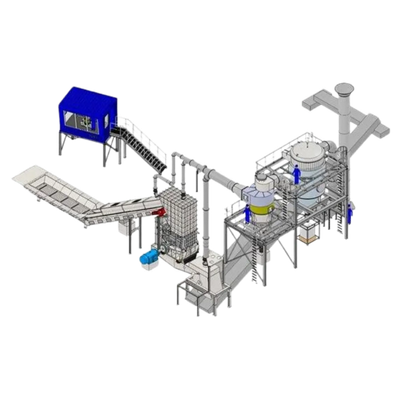

ORM - Aluminum Shredder for Recycling and Remelting

Oberländer Recycling Maschinen GmbH offers an advanced aluminum shredder system equipped with star rings, optimized for the recycling of aluminum scrap. Designed specifically for use in aluminum remelting plants or for producing high-quality wrought aluminum alloys, the shredders excel in the separation of impurities such as iron alloys, copper components, surface coatings, plastics, and wood. The system, which builds on the brass knuckles shredder technology developed in the 1970s, provides a superior approach compared to traditional hammer shredders. With rotating brass knuckles featuring sharp edges, the shredder effectively tears and breaks down contaminants, enhancing the purity of the recovered material. Additionally, a dry dedusting system with ATEX-approved explosion-proof capabilities captures volatile components, offering a cost-effective alternative to wet scrubbers. The star ring design allows for efficient handling of impurities, achieving a higher bulk density in processed aluminum, suitable for remelting processes.

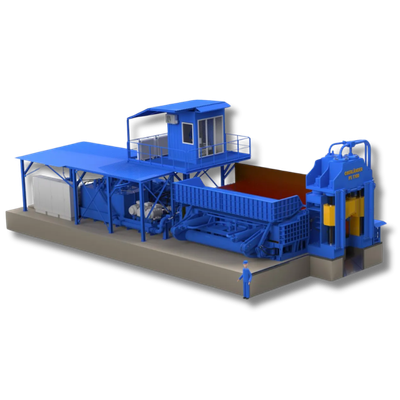

ORM - Special Shears for Production Companies

The product range also includes special scrap shears and presses for production companies to shred or compact waste and material residues on site. This saves logistics costs and increases revenue. The systems are adapted for production operations and can be loaded with existing handling equipment (forklifts or indoor cranes) and work fully automatically.