Octagon Precision (India) Pvt. Ltd. products

Calibration Lab Equipments - Universal Length Measuring Machine

Octagon - Universal Length Measuring System For Calibration Metrology

A model of universal length measuring machine specially designed for high precision parts of Horology, Aerospace & Micro Precision industries. Machine horizontal base is made of rugged cast-iron with guide-ways for the measuring head and the tailstock positioning. Absolute Measuring Range: 40mm Differential Measuring Range: 80mm. Resolution: 0.1µm Display System: DRO (Digital read-out system)

Calibration Lab Equipments - Gauge Block Measuring Machine

Octagon - Gauge Block Comparator

Octagon Gauge block comparator GBC 170 precision gauge block measuring systems

designed with two electrical high resolution length indicators (sum measurements)

as recommended in ISO 3650 .

Shaft Measuring Systems - Camshaft Metrology Systems

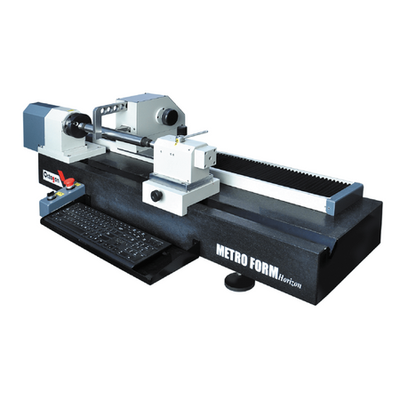

Octagon MetroForm - Horizon Camshaft Measurement Machine

The MetroForm - Horizon is a specialized machine designed for precision measurement of camshafts. It features a unique adjustable radial measuring head tailored for the accurate assessment of universal cam lobes. This system ensures high-precision measurements which are crucial for applications in engine manufacturing and maintenance. The machine's ability to measure both simple and complex cam profiles makes it essential for industries where camshaft functionality impacts performance. By incorporating advanced metrology technology, this system provides detailed insights into the wear and functionality of cam lobes, supporting precise engineering adjustments and quality control in automotive and mechanical engineering fields.

Display’S Controller & Gauging System

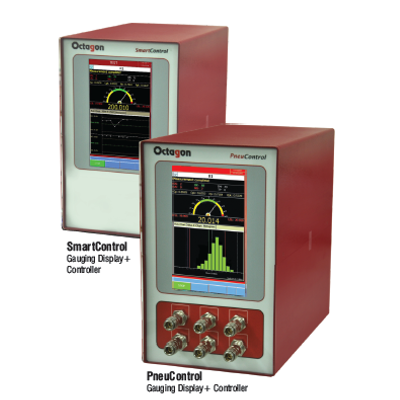

Octagon - Pneu Control System

State-of-art displays which caters to emerging needs of Industry 4.0 requirements. Single channel / multi channel gauging displays for inductive probing sensors and piezo sensors based gauging displays for air gauging.

Other Products

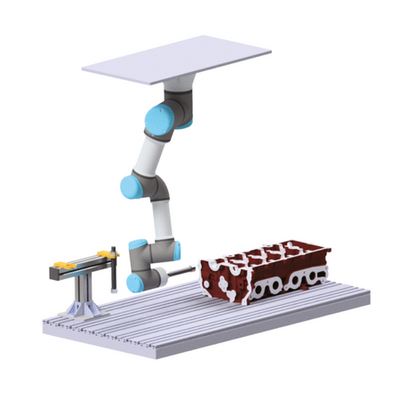

Octagon - Robotic Inspection System

The Robotic Inspection System by Octagon Precision is engineered for meticulous automated inspection and quality assurance processes. It is designed to integrate smoothly within industrial environments, allowing for comprehensive measurement and analysis of complex components. The system supports dynamic adaptation to various inspection needs, thereby enhancing precision and reliability in detecting defects or discrepancies in manufactured goods. It leverages advanced sensors and software algorithms to ensure high accuracy and repeatability, making it essential for industries requiring stringent quality standards. This system aids in reducing manual inspection errors and accelerates the inspection process, thus optimizing production efficiency and consistency.