Oil Pollution Services (OPS) Ltd. products

OPS - Electrocoagulation Wastewater Treatment System

OPS Electrocoagulation Wastewater Treatment solutions integrate advanced Electrocoagulation and Dissolved Air Flotation (DAF) processes, offering a superior wastewater treatment method tailored for diverse applications such as oily water, leachates, food and beverage wastewater, and car wash water. This innovative combination is effective against various contaminant types and waste stream compositions—ranging from oily water and food industry wastewater loaded with fats, oils, and greases, to car wash water, contaminated groundwater, landfill leachates, fracking water, and more. The electrocoagulation process operates by passing an electrical current between electrodes through the water stream, utilizing sacrificial metal plates specifically selected based on the contamination type and water properties. This approach, combined with DAF, ensures high throughput, energy efficiency, and minimal maintenance. The OPS system stands out for its cost-efficient 'off-the-shelf' integration with proprietary processes, delivering reliable performance and optimized life-cycle costs tuned to individual site conditions.

OPS - Model DAF - Dissolved Air Flotation System

The OPS Dissolved Air Flotation (DAF) system is designed to clarify wastewater by effectively removing suspended solids, enabling both product recovery and water treatment that aligns with environmental regulations. With over a decade of experience, OPS has specialized in designing, manufacturing, and installing DAF systems across various industry sectors. Both stationary and mobile units are equipped with features to minimize operating costs and maintenance overhead. The DAF system demonstrates enhanced performance when integrated with an electrocoagulation unit, particularly in wastewater with high levels of fats, oils, or greases. Technically, the system supports a hydraulic loading rate of 1-2m3/hr per m2 of hydraulic separation area and a solids loading rate measured in kg/hr per m2. Known for engineering cost-effective solutions, OPS combines off-the-shelf products with high-throughput proprietary processes for tailored, site-specific efficiencies. This dedication ensures reliable performance and optimized lifecycle costs.

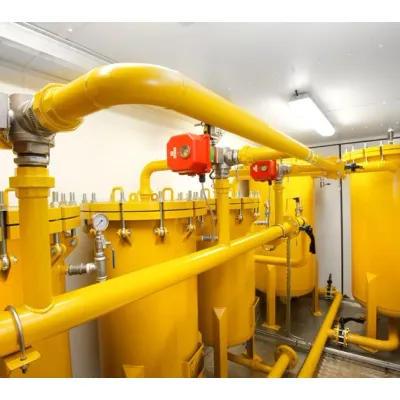

OPS - Filtration Unit

OPS Filtration represents a reliable and user-friendly solution central to waste filtration and de-watering. The OPS range of filtration vessels effectively removes insoluble particulate matter from wastewater through advanced filtration systems including parabolic screens, back-washable and dynamic sand filters, cartridge filter vessels, and media absorption filters. OPS employs a variety of filtration techniques optimized for specific applications. The key parameters for filter sizing are solids loading and flux rate through the filter bed, and it's crucial to consider the water's nature, such as oil content and polyelectrolyte residue. Given the unpredictability of water in many applications OPS deals with, backwashing is necessary for sand and media filters, requiring a constant water supply. When specifications allow, OPS integrates cost-efficient off-the-shelf items to reduce capital expenditure. The integration of high-efficiency processes with best-in-class process control ensures consistent performance, reliability, and optimized life cycle costs for OPS's engineered solutions.

OPS - Model AEV - High Pressure Mechanical Scrubber

The OPS adiabatic expansion valve (AEV) sand scrubber is a high-efficiency, low-maintenance mechanical attrition scrubber designed for handling materials up to 35mm, including sand, soil, chippings, and more. Utilizing high-pressure water jets, the scrubber effectively processes a slurry loaded with solid particles. The proprietary design ensures minimal wear on the pipe walls and reduces maintenance needs, which extends the device's lifespan. The AEV meets specific pressure directives and has seen extensive use in different regions including the EU, Canada, Africa, and the Middle East. It pairs seamlessly with OPS's Electrocoagulation and Dissolved Air Flotation (DAF) systems to treat various waste types such as sludge lagoons, car wash, and interceptor waste. The unit can also be configured for additional contaminant removal like heavy metals. Advantages include the capability to reduce oil on solids to levels below 500ppm, with throughput rates of up to 40t/h per scrubber, and scalable to 120t/h with multiple units. It features a simple, fully PLC-controlled interface and can be part of modular treatment systems.