- Home

- Companies

- Openchannelflow

- Products

Openchannelflow products

Flumes

Openchannelflow - Parshall Flumes

The Parshall flume is an economical and accurate way of measuring the flow of water in open channels and non-full pipes. The flume was originally developed to measure surface waters, water rights apportionment, and irrigation flows, but its use has expended to include measuring the flow of sewage (both in pipe and treatment plants), industrial discharges, and seepage from dams. As a class of 22 standard sizes, the Parshall flume is the most commonly used and widely recognized flow measurement flume.

Openchannelflow - Palmer-Bowlus Flume

Unlike most other flume styles developed for irrigation flows and then applied to other uses, the Palmer-Bowlus Flume was specifically designed to measure sanitary sewage / wastewater flows from the outset. The Palmer-Bowlus Flume is widely used to measure industrial discharges, municipal sewer flows, and influent / effluent at wastewater treatment plants and is second only to the Parshall Flume in popularity.

Openchannelflow - Flumes

The Dust Bowl experienced by the United States during 1930’s saw the establishment of the Soil Conservation Service (SCS) on April 27, 1935. The SCS was established as a permanent agency the US Department of Agriculture with a mission to conserve the nation’s soil and water resources. With this mandate, researchers at the SCS began the investigation and development of a class of flumes suitable for use in measuring agricultural flows. The H Flume, so called because it was the eighth in a series of flumes investigated, combined the flow sensitivity of a narrow angle V-notch weir with the flat floor and self-cleaning properties of a flume.

Shelters

Openchannelflow - Fiberglass Single-Piece Equipment Shelters

For year-round protection of equipment, Openchannelflow offers Fiberglass Single-Piece Equipment Shelters. These shelters are perfect for housing equipment, instruments, and chemicals and are available in a range of widths and lengths to suit your exact needs.

Openchannelflow - Fiberglass Modular Equipment Shelters

For year-round protection of larger equipment, Openchannelflow offers Fiberglass Modular Equipment Shelters. These shelters are designed for headworks, UV systems, chemical feed, and large electrical system components. Modular construction allows for flexibility and equipment access that is difficult for smaller, single-piece shelters or enclosures to provide.

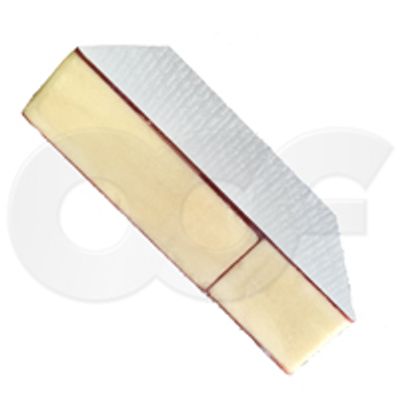

Openchannelflow X-Web - Fiberglass Shelters Construction

At the core of each Openchannelflow shelter is our X-Web sandwich panel design. The design sandwiches an insulating foam core between two fiberglass skins. To insure maximum strength and eliminate any chance of delamination, after each panel of insulation is applied, it is encapsulated in fiberglass. The result is a beam of fiberglass that is bonded to the inner and outer fiberglass skins - tying them together and increasing the stiffness / strength of the panel. Insulation values are determined by the customer’s needs, from R~7 to R~28. Pound for pound fiberglass is stronger than sheet metal. It will not rust and it is perfect for outside use or at locations near water, especially salt water, or the corrosive environments found at treatment and chemical plants.

Manholes

Openchannelflow - Fiberglass Packaged Metering Manholes

Openchannelflow fiberglass Packaged Metering Manholes (PMMs) solve the difficult problem of how to measure piped flows below grade. Starting with our industry leading fiberglass manhole tube, Openchannelflow integrates a flow device, cover, base, and access ladder. The result is a single-piece, watertight, and corrosion-resistant structure from which operators can accurately (and safely) measure and sample flows.

Openchannelflow - Fiberglass Energy Absorbing Manholes

For a Flume or Weir to work correctly, the flow must be sub-critical and tranquil. Many times, however, site conditions don’t allow the development of this type of flow. For those occasions, Openchannelflow has developed fiberglass Energy Absorbing Manholes. Fiberglass Energy Absorbing Manholes are a way to slow the velocity of water through a pipe system in a way that`s cost-effective and which requires little in the way of line downtime. Energy Absorbing Manholes can be placed directly upstream of Packaged Metering Manholes. The flow is slowed and conditioned in the Energy Absorbing Manhole and then smoothly flows into the Packaged Metering Manhole to be measured. Energy Absorbing Manholes eliminate the need for costly line excavations, replacement, or resloping. Installation can also be concurrent with a Packaged Metering Manhole – reducing labor and machinery costs.

Openchannelflow - Fiberglass Diversion Manholes

Openchannelflow fiberglass Diversion Manholes help operators control, direct, and distribute below-grade non-full pipe flows. Diversion Manholes are available in multiple configurations, including: Interior drops, Y-channels, J-bends. Diversion Manholes allow for drop-in-place installation and can be provided with gated channels to direct flow to different downstream locations. Like our other fiberglass manholes, Openchannelflow Diversion Manholes are single-piece, watertight, and corrosion-resistant. When Y-channels or J-bends are provided, fiberglass benching is included around them. The benching eliminates the need to pour concrete benching in the manhole and has a molded-in non-slip diamond plate pattern. The diamond plate doesn`t wear or blind like gritted surfaces and is easy to maintain.

Openchannelflow - Storm Water / Screening Manholes

Storm Water / Screening Manholes are a class of structures that Openchannelflow has developed to removed trash, grit, floating debris, and oil from collection systems. Using our proven fiberglass manhole tubes, Openchannelflow integrates a screenings structure specific to your site`s needs. Just like our other fiberglass manholes, Openchannelflow Storm Water / Screenings Manholes are single-piece, watertight, and corrosion resistant. Factory integrated they are cost effective and require little line downtime. Dig it! Drop it! Done!