Operational Group Limited products

Dryer Optimisation

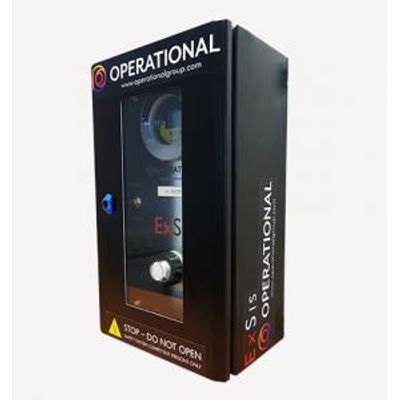

Model ExSis - LEL Gas Monitoring Systems

Lower Explosive Limit (LEL) Detection: ExSis- Our flammable Gas monitoring systemThe ExSis flammable Gas detection unit from Operational is a catalytic (CAT) or infrared (IR) solvent monitoring safety system. It is a high quality LEL gas monitoring system that uniquely provides a complete answer to the demands of safety standards in an industrial environment. The intended designs of the Operational LEL systems comply with the requirements of PL d according to EN ISO 13849-1 and have been certified by TUV to be used in safety related applications to this level, as required by EN1539 Systems are modular, compact and can be fitted into any type of duct, oven, dryer or enclosure.

Air Pollution Control

Regenerative Thermal Oxidisers (RTO’s)

The oxidation of VOC’s contained in exhaust air streams involves a chemical reaction between the VOC’s and the oxygen in the air, usually at an elevated temperature, and forming carbon dioxide and water vapour. The RTO is an extremely efficient thermal oxidiser that uses a number of ceramic or ‘hot brick’ beds to absorb heat from the exhaust gas. It then uses this captured heat to preheat the incoming process air stream and destroy air pollutants emitted in the exhaust air stream at temperatures ranging up to 1000deg C.

Tubular Electrostatic Precipitators (ESP)

An electrostatic precipitator is a filtration device that removes fine particles, such as dust, smoke and liquid droplets, from an exhaust air stream using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit. In contrast to other techniques which apply energy directly to the flowing fluid medium, an ESP applies energy only to the particulate matter being collected and therefore is very efficient in its consumption of energy in the form of electricity.

Wet Scrubbers for Air Pollution Control

Wet scrubbers are used for cleaning air and other gases of various pollutants and dust particles or substances considered harmful to the environment, and which may be removed or neutralized. Wet scrubbing works via the contact of target compounds or particulate matter with the scrubbing solution. Solutions may simply be water (for dust) or solutions of reagents that specifically target certain compounds. Process exhaust gas can also contain water-soluble toxic and/or corrosive gases like hydrochloric acid (HCl) or ammonia (NH3). These can be removed very well by using a wet scrubber.

Bio-Filtration and Bio-Trickling Filters

Bio-filtration is a pollution control technique using a bioreactor containing living material to capture and biologically degrade pollutants. Common uses include the micro biotic oxidation of contaminants in air. When specifically applied to air filtration and purification, bio-filters use microorganisms to remove air pollution. The air flows through a packed bed and the pollutant transfers into a thin biofilm on the surface of the packing material. Microorganisms including bacteria and fungi are immobilized in the biofilm and degrade the pollutant. Trickling filters and bio-scrubbers rely on a biofilm and the bacterial action in their recirculating waters.

Heat Recovery

Gypsum Calcination Kilns

With calcining temperatures of approximately 180 oC and high particulate dust loading in the exhaust air stream, gypsum calcination kilns require a bag filter upstream of the air to air heat exchangers.By employing air to air heat exchangers to recover heat, our systems will return hot air for use in pre-heated combustion air and as make-up process air. Return on investment is delivered in approximately 18-24 months.

Aluminium Smelting Furnaces

An aluminium smelting process exhausting hot combustion gases from a natural gas fired combustion chamber. Heat is recovered from the hot combustion gases at temperatures of up to 600 oC and transferred, via an air to thermal oil, stainless steel heat exchanger, to a thermal oil ring main circuit. This thermal oil ‘run-around system’, operating at 270 oC, is then used to transfer heat to pre-heat the combustion air for the furnace gas burner system. A 2 year return on investment was achieved.