- Home

- Companies

- Optomec Inc.

- Products

Optomec Inc. products

3D Printed Electronics

Optomec - Printed Antennas

A new high volume process is available that lowers manufacturing costs for antennas used in mobile devices. The new process works with standard injection molded plastics – no special additives or coatings are required. Based on Aerosol Jet technology, the digital process prints conformal antennas using conductive nanoparticle silver inks. The printing process accurately controls the location, geometry and thickness of the deposit and produces a smooth mirror-like surface finish to insure optimum antenna performance. No plating or environmentally harmful materials are used in the process.

3D Printed Electronics - Aerosol Jet System

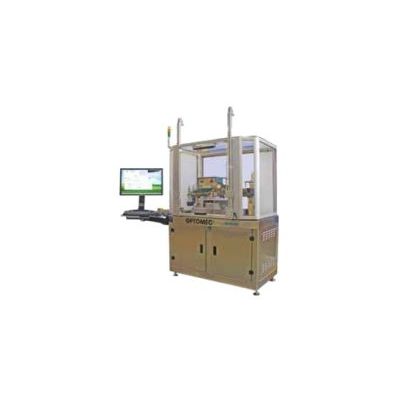

Aerosol Jet - Model 200 Series - Printer

Aerosol Jet 200 Series Systems are ideally suited for universities, ink developers, and others exploring the benefits of additive manufacturing for electronic applications.

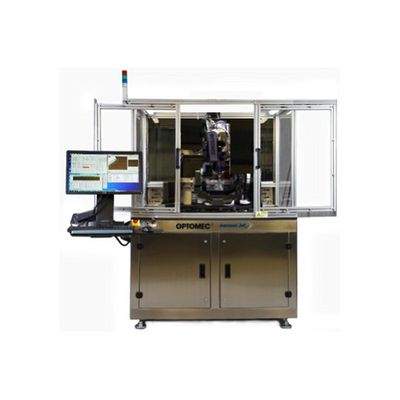

Aerosol Jet - Model 300 Series - Printer

Aerosol Jet 300 Series systems are ideally suited to develop next generation processes and devices for photovoltaic, touch screen displays, 3D interconnects and other printed electronics and biologics applications. A number of Aerosol Jet 300 Series system configurations are available to meet your specific application requirements.

Aerosol Jet Systems

Aerosol Jet - FLEX Systems

The Aerosol Jet FLEX system is a scalable platform capable of addressing a wide array of 2, 2.5, and 3D printed applications requirements. The system comes equipped with an Optomec closely coupled print module ideally suited for high resolution printing of electronic circuits and devices for rapid prototyping, product development and printed material evaluation. The Aerosol Jet FLEX system comes with 3-axis of coordinated print motion. Optional add-ons include wide feature printheads; 1W, 830nm IR Laser; 340nm UV Cure solution; and a tilt & rotate trunnion making the system full 5-axis of coordinated motion capable.

Aerosol Jet - Print Engine

The Aerosol Jet Print Engine enables next-generation product process development to factory floor production of 3D advanced packaging, sensors, and circuits used in smart mobiles devices, automotive, medical and other electronic products. The Print Engine, with its advanced process controls and print cassettes, is Optomec’s most scalable and versatile printed electronics platform to date. With its scalable architecture up to two simultaneous printheads can be supported via a single process controller. Process controllers can be multiplexed together enabling up to four or more printheads in a single configuration to meet high volume production requirements. Aerosol Jet’s material deposition versatility enables it to meet a wide range of current and next-generation electronics manufacturing requirements across a broad range of industries. The Print Engine’s architecture facilitates custom and OEM automation platform integration.

Lens System

Optomec - Model CS 150 - Lens System

The entry level, low-cost LENS 150 system is ideally suited for universities, researchers, metal powder developers and others exploring the benefits of metal additive manufacturing. The system is built on industry proven LENS technology and can be used for additive manufacturing and repair applications for small parts.