- Home

- Companies

- Paul GmbH & Co. KG

- Products

Paul GmbH & Co. KG products

Sieve & Filter Media - Metal Wire Mesh

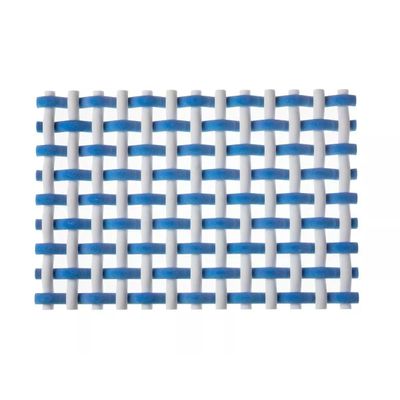

Plain or Linen Weave

Plain weave is the most commonly used weave. Its advantage lies in its simplicity enabling the tightest of wire crossings and highest precision. Every second wire is bound, with warp and weft wires constantly alternating over and under each other and fixing each other in place. The plain weave guarantees the most precise mesh opening of all wire cloths produced in any comparable fineness range, providing clear advantages across filtration, sieve technology and screen-printing. The linen or plain weave is the origin of all types of wire cloths. Derived from braiding, longitudinal threads (warp) and transverse threads (weft) are woven together. The weft thread runs under the warp thread in an undulating pattern, then over it the next time and so on. In this way, the threads fix each other in place allowing production of very precise mesh openings with this type of weave.

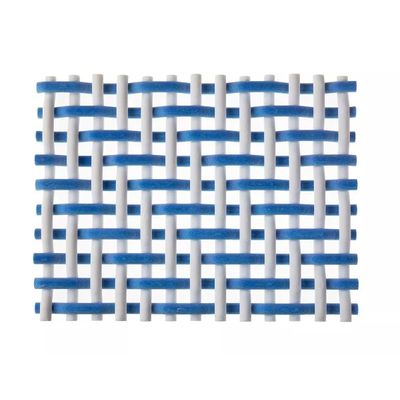

Twilled Weave

The twilled weave is a weaving method that offers many possible variations. In the standard version, two warp wires are bound in pairs by the weft wire with a subsequent offset by one wire. This special type of weave can apply to both warp and weft threads, which in itself forms the basis for the wide range of variations in the family of twilled weaves. This method is usually chosen when the wire is so thick in relation to the mesh size that it would be unable to withstand the stress of the weaving process on its own. Good weave stability is achieved using the latest weaving technology. The mesh is diamond-shaped and the weave pattern has a typical diagonal pattern (ridge). Twilled weaves are used, for example, for screen and filter products.

Value Added Products

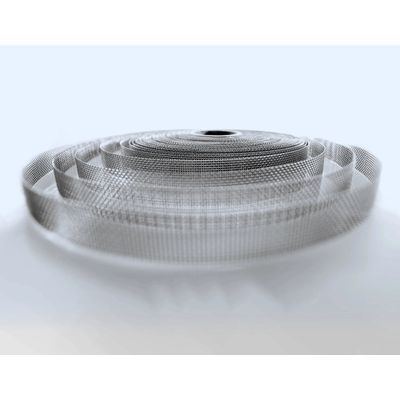

Cloth Strips / Coil Strips

Cloth strips/coils without a welded seam can be supplied up to max. 3,200 mm (max. weaving width). If wide cloth strips/rolls are required, they can be manufactured using suitable welding processes. Cloth strips of up to 6 mm can be produced from the 1.00 m / 1.35 m / 1.53 m / 2.04 m / 3.20 m standard widths in stock according to customer requirements. Cloth rolls are produced in standard lengths of 30 / 60 / 100 running metres. In some projects, wire cloth rolls of up to 600 running metres can be produced without a welded seam. With welded seam, > 1000 running metres can be produced by being rewound. As an additional treatment, we offer various cleaning processes (hydrous / ultrasonic / thermal) as well as calendering, solution annealing and vacuum annealing (high / fine vacuum).

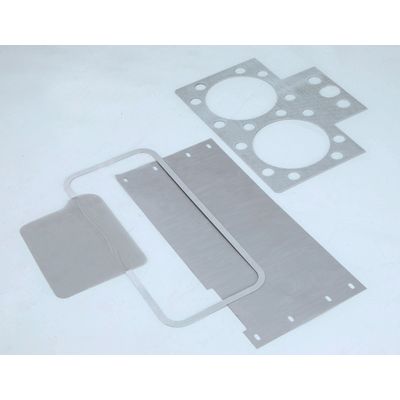

Punched Parts & Laser / Plasma Cuts

We make punched parts in presses with cutting tools as well as thermally cut blanks (fibre laser/plasma) from cloth, metal fibre cloth, laminates and perforated sheets, as well as metal gaskets as flat gaskets and/or diaphragm gaskets. Our system technology is designed for sheet thicknesses from 8 mm stainless steel to 500 mesh. Circular blanks or other geometric shapes from 4 mm to 2,200 mm are possible. As larger contours greater than 400 mm are usually requested in small quantities, production is carried out by fibre laser cutting. If blanks with a diameter of more than 2,200 mm are required, these are manufactured from several individual parts and then welded together.

Shaped Parts / 3D-Cut-To-Size Parts

Presses are also used to produce shaped parts / deep-drawn parts / 3D-shaped blanks. The system technology is designed for all types of metallic raw materials (cloth, laminates, perforated sheets, sheet metal). A wide range of machines is available for this purpose. The deep-drawing of cloths and laminates is a particular challenge. As the wire cannot stretch as much as sheet metal during deep drawing, a great deal of experience is required for extreme deformations.