Paulo services

Heat Treating

Austempering Services

When workpieces require added hardness, higher impact and fatigue strength, increased ductility, resistance to embrittlement higher wear resistance, Paulo’s state-of-the-art austempering process ensures your parts are finished to specification with minimal distortion.

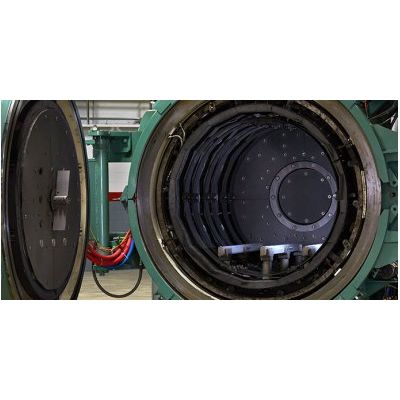

Vacuum Heat Treating Service

Precise, system-wide temperature controls ensure consistent quality. Some of the biggest names in manufacturing – including General Motors – trust Paulo’s Vacuum Heat Treating range of heat treating services. Our computer-controlled vacuum heat treating ensures consistent temperatures and other key variables, ensuring reliable results and uniformity across even the largest lot of parts. Our PICS software tracks and documents every variable across your entire projects, including thermocouple data and furnace cycle reports.

Solution Treating & Precipitation Hardening Service

Sometimes referred to as “age hardening,” precipitation hardening is a technique intended to increase a material’s resistance to increase strength. This process is used with many materials, including maraging steels, aluminum, some stainless steels, super alloys and more.

Continuous Hydrogen Belt Heat Treating

16` Wide Belts Capable of High Volume. Computer Controlled for Consistent Results. Bright Processing of Stainless Steel. Copper, Nickel, Silver, and Gold Brazing. Serving the Aerospace, Automotive, Appliance, and other industries.

Metal Finishing

Paulo - Zinc Plating

Protecting high-volume metal components for automotive and other industries. Paulo’s high-volume, computer-controlled automatic barrel plating lines, combined with our proven engineered processes, delivers zinc-coated parts that meet even the most stringent requirements. Our zinc electroplating, non-corrosive finish protects the base metal of your components.

Paulo - Zinc Phosphating

Meeting stringent standards for uniform, non-conductive coatings. Paulo’s zinc phosphating processes give your metal services non-conductive, non-metallic properties. Our automatic barrel phosphating equipment enable us to process large-lot sizes on a very short timetable. Our multiple processing capabilities include post coatings with oils and sealants for added corrosion resistance or additional lubricity.