Pegasus Vertex, Inc. software

Drilling Software - Drilling Operation

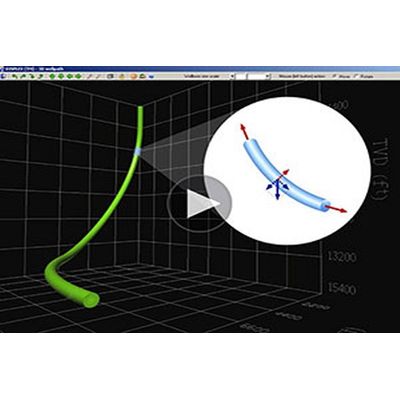

Pegasus Vertex - Torque and Drag Model Drilling Software

Today’s more prevalent extended-reach directional wells mean that tubulars are exposed to greater amounts of torque and drag (T&D). If this torque and drag is not evaluated, this can result in stuck pipe, pipe failures, and costly fishing jobs.

Drilling Software - Mud Reporting

Pegasus Vertex - Advanced Drilling Mud Reporting Model Drilling Software

Mud is generally synonymous with drilling fluid. It is used in the rotary drilling process to: clean the wellbore, carry out cuttings, exert hydrostatic pressure, cool, and lubricate the drill string and bit. Mud can lead directly or indirectly to most drilling problems. If the drilling fluid does not behave properly, it may lead to many serious well problems, including well abandonment. Meanwhile, the additives required to maintain the mud in good condition are quite costly. Mud engineers need to keep track of the usage of these additives.

Drilling Software - Casing Wear

Pegasus Vertex - Casing Wear Prediction Model Drilling Software

Casing wear is a continuous concern during the process of drilling and workover. Casing integrity relies highly on the preliminary casing design, which requires to consider both well path and casing sustainability to withstand all the operations. Improper placement of casing may end up in catastrophic incidents such as oil spills, blowouts or even the loss of a well. Remediation of casing failures can raise the field operation cost dramatically and be time-consuming.

Drilling Software - Cementing Job

Pegasus Vertex - Centralizer Placement Model Drilling Software

Casing centralization is one of the key elements to ensure the quality of a cementing job. It does so by preventing mud channeling and poor zonal isolation. While centralizers are used extensively, well problems continue to arise due to poor cementing jobs. The challenge that both operators and service companies face is to choose the right type of centralizers and place the correct amount of them in the optimum position on the casing to achieve a good standoff profile.

Drilling Software - Wellbore Cleanup

Pegasus Vertex - Wellbore Cleanup Model Drilling Software

The first step to ensure an optimum completion is to remove leftover drilling fluid residue and casing debris. This requires that the drilling mud be changed out with solids-free completion fluids. Completion fluid displacement involves multiple fluids sequenced in circulation. Varying flow rates, flow paths, circulation subs, multiple stages and possible HTHP conditions make it increasingly difficult to determine pump pressures and bottomhole ECDs. Despite these significant challenges, however, detailed planning of the wellbore cleanup operations can help ensure both job success and well productivity.