- Home

- Companies

- Perar s.p.a

- Products

Perar s.p.a products

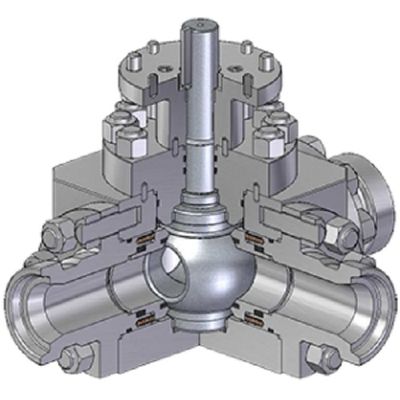

Three-Way Ball Valves

Three-way ball valves is a very versatile design which can be used for different applications by combining the T or L port with dedicated actuation. The valve design is based on a solid forged block with three closures and a trunnion mounted ball.

Floating Ball Valves

Model FC - Standard Floating Ball Valves

2/ 3 pieces bolted body design. They are manufactured in a wide range of sizes and pressure classes typically from forgings.

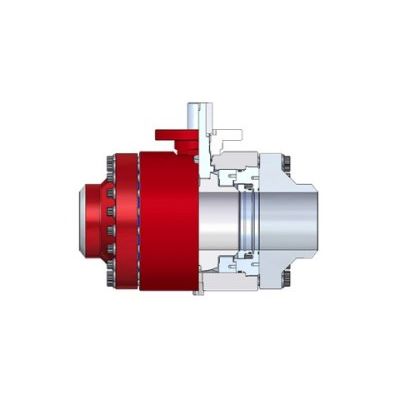

Compact Ball Valves

Standard - Trunnion Mounted Ball Valves

Compact Ball valve is a manufacturer standard design suitable to combine a compact ball valve design with robustness and reliable performances. The valves do not rely on lubricant or grease to assist sealing between the ball and seat also when metal-to-metal sealing is used. The valve design is based on trunnion mounted or support plate configuration in order to get the operating torque as lower as possible.

Model FA - Swing Check Valves

Compact swing check valve is a manufacturer standard design suitable to combine a compact ball valve design with robustness and reliable performances. The valve design is based on swing clapper full opening configuration with dedicated end flanges to get the operating torque as lower as possible.

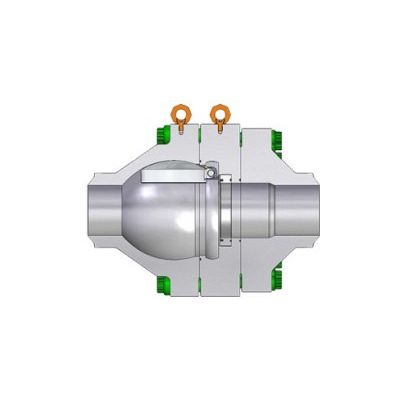

Split Body Side Entry Ball Valves

Model EB - Split Body Side Entry Ball Valves

The ball of trunnion mounted configuration is supported by bearing plates hold by the end adaptors. In such a way the pressure loads are transferred to the valve body granting a smooth rotation of the ball with low torque levels and reduced seat seal wear. PERAR Trunnion Mounted Bolted Body Side-Entry Ball Valves represent the basic design standard. They are manufactured in a wide range of sizes and pressure classes typically from forgings.

Model EC - Split Body Side Entry Ball Valves

The ball of trunnion mounted configuration is supported by external trunnions bolted to the body. In such a way the pressure loads are transferred to the valve body granting a smooth rotation of the ball with low torque levels and reduced seat seal wear.

Fully Welded Body Trunnion Mounted Side Entry Ball Valves

Model WB - Trunnion Mounted Configuration Ball Valves

The ball of trunnion mounted configuration is supported by bearing plates hold by the end adaptors. In such a way the pressure loads are transferred to the valve body granting a smooth rotation of the ball with low torque levels and reduced seat seal wear. On PERAR Trunnion Mounted Welded Body Ball Valves the potential leak paths are minimized making them suitable for buried installations and in general for gas transportation. The weight and overall dimensions are optimized by applying a shaped design. They are manufactured in a wide range of sizes and pressure classes from forgings.

Top Entry Ball Valves

Model PSL3-PSL4 - Subsea Top Entry Ball Valves

Subsea top entry ball valves are designed according to API6DSS, API6A, API17D with the addition of customer requirements when present. The valves do not rely on lubricant or grease to assist sealing between the ball and seat. Metal-to-metal sealing is used between the ball and seat and non-elastomeric seal are provided between the seat and body. Metal-to-metal sealing is also provided between body-to-bonnet and stem-to-body (optional).The Subsea ball valves are actuated by Perar hydraulic actuator or gearbox as requested.

Subsea Actuators

Model DA - Subsea Linear Hydraulic Actuators

Subsea linear hydraulic actuators for slab gate valves are designed for deep water application with hydraulic operating pressure of 3000psi or 5000psi as per Customer requirements. Actuators are design in accordance with API17D with the addition of customer requirements when present. All models are equipped with mechanical override intervention mechanism and can be provided with remote indicator (continuous or limit switches). The mechanical override can be designed not compressing the spring and bypassing the hydraulic piston

Model FAI - Subsea Quarter Turn Actuator

Subsea quarter turn hydraulic actuators are designed for deep water application with hydraulic operating pressure of 3000psi or 5000psi as per Customer requirements. Actuators are design in accordance with API17D with the addition of customer requirements when present. The core mechanism of the actuator can be Rack & Pinion or Helical Spline. All models can be equipped with mechanical override intervention mechanism and all models can be diver or ROV retrievable. Helical Spline mechanical override can be designed not compressing the spring.