Performance Distillation Solutions products

Random Column Packing

PDS Pro-Pak - High-Efficiency Random Column Packing for Distillation

Pro-Pak represents a highly efficient choice in random packing for distillation, effective under both atmospheric and low-pressure conditions. Complying with rigorous international standards, such as ASTM D2892, it is optimized for the distillation of crude petroleum. Available in multiple sizes, Pro-Pak facilitates high-efficiency separations in numerous operational scales, from bench research to pilot and technical-scale productions. Its design prioritizes high purity, compactness, energy efficiency, and low loading, catering to demanding industries like petroleum, food and beverage, organic and green chemistry, electronic chemicals, and isotope processing. Constructed in 316 Stainless Steel, 400 Monel, and other specialty metals, it ensures enhanced corrosion resistance and suitability for diverse applications. This makes it ideal for laboratory, pilot, and small production scale distillation columns.

PDS Pro-Pak® - Model IMTP-25 - Metal Tower Packing for Distillation and Absorption

The PDS-IMTP-25 is a precision-engineered metal tower packing solution designed to optimize mass transfer in distillation and absorption columns. The packing is characterized by its 25 mm IMTP-style structure which ensures high efficiency in separation processes. It boasts a high surface area of 225.8 m²/m³ and a void fraction of 96.6%, enabling it to handle a broad flow range while maintaining a low-pressure drop. This makes it particularly suitable for industrial applications such as petrochemical processing, refining, biofuel production, chemical manufacturing, and environmental scrubbing. The packing is tailored to work effectively when paired with a column diameter-to-packing ratio (D/d) of 20. Performance Distillation Solutions offers customized engineering support to meet specific application needs, reinforcing its commitment to energy-efficient and high-performance separation systems.PDS - Model MPALL-25 - Metal Pall-Ring Packing for Enhanced Mass Transfer

The PDS-MPALL-25 metal pall ring is designed to optimize mass transfer operations within distillation processes. It features a high surface area of 206.7 square meters per cubic meter and a 94.8% void fraction, which contribute to its efficiency in enhancing column performance. This metal pall ring is particularly suitable for applications requiring robust and durable packing materials capable of sustaining high capacity operations. The air-water pressure drop data, with a diameter ratio of D/d = 20, highlights its efficacy in managing pressure within columns. Overall, the PDS-MPALL-25 is an ideal choice for those seeking reliable and effective mass transfer components in various industrial settings, where it can contribute to improving system throughput and performance.

Turnkey Thermal Process Systems

PDS - Model Academia - Comprehensive Range for Thermal Process Engineering

ILUDEST designs/manufactures a comprehensive range of Teaching Units for Thermal Process Engineering. Comprehensive range of computer controlled thermal processing equipment. Designed to meet the unique challenges of education and research. Examples of features include additional sensor packages and sampling ports. Additional documentation for educators and students included.

LabTech Instruments

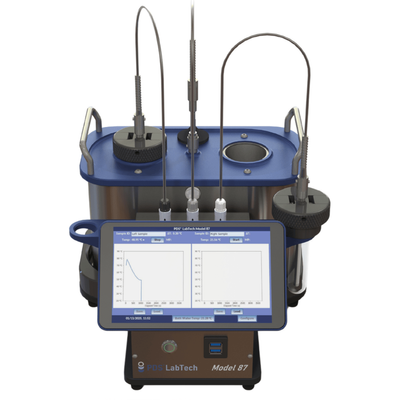

PDS LabTech - Model LTM-87 - Automated Petroleum Wax Melting Point Apparatus

The PDS LabTech Model 87 is an advanced laboratory instrument designed for accurately determining the melting point of petroleum, paraffin, and scale waxes using the cooling technique as per the ASTM D87 Test Method. This fully automated system integrates calibrated traceable RTD probes to eliminate the traditional mercury thermometers, allowing dual test cells within a compact, removable bath. Once the sample melts, the user interacts with a straightforward touchscreen GUI which displays test status visually and audibly. The results can be exported via USB 3.0 ports. Enhanced with a wireless keyboard, the device minimizes operator variability, boosting throughput and accuracy. Critical features include an Air/Water Bath RTD Temperature Sensor and a Borosilicate Glass Sample Vial with specific dimensions, ensuring precision and safety in operations. It accommodates ambient temperatures ranging from 15 °C to 30 °C and features a water bath sight gauge for level checks, exemplifying its operational proficiency and safety compliance.