Pipefusion Services Inc. products

Fabricated Fittings

Pipefusion has complete engineering services and over 9,000 sq. ft. of indoor manufacturing facilities. If we cannot source a fitting, we will manufacture it to your design specifications in our fabrication shop.Our proprietary joining methods include several patents on custom fittings which will ensure that you and your organization are making an informed decision.

Polyethylene Pipe

Pipefusion - Solid Wall Polyethylene Pipe

Pipefusion is a supplier of solid wall HDPE pipe which is available in sizes from 1” to 63” with a wide range of wall thickness available. HDPE solid wall pipe is also available in Iron Pipe Size (IPS), Ductile Pipe Size (DIPS) as well as metric sizes. The benefits of solid wall HDPE pipe, over traditional piping materials, include:

Pipefusion - Urecon Pre-Insulated Pipe

Pipefusion is a supplier of Urecon pre-insulated pipe and heat trace systems which are ideally suited for the harsh conditions commonly found in mining.

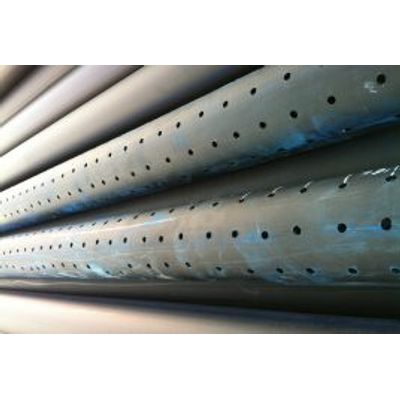

Pipefusion - Perforated and Slotted Pipe

Pipefusion can source perforated and slotted pipe which is available in a number of industry standard sizes. HDPE perforated and slotted pipe is the material of choice for applications requiring water drainage, leachate systems, cable protection, ducting and landfill gas dissipation.

Pipefusion - Profile Wall Pipe

Pipefusion is a supplier of Weholite, manufactured by Uponor, which is a large diameter structural profile wall pipe made from special high density polyethylene (HDPE) resin. With Weholite, raw material properties have been combined with advanced product technology to create a lightweight engineered pipe with superior loading capacity.

Molded Fittings

Pipefusion - Butt Fusion

The butt-fusion method of joining is by far the most common method of connecting polyethylene pipe in all diameters. The ends of polyethylene pipe when heated and brought together under pressure with specialized equipment form one continuous “leak proof” pipeline. Properly made, a pipe fusion is as strong as the pipe itself and has the same life expectancy. Pipefusion has the ability to source butt fusion fittings in a wide variety of sizes up to 63″ and types, including:

Pipefusion-Socket Fusion

Socket fusion is distinguished from butt-welding by using custom-shaped and sized heating plates rather than a basic flat surface. These heads allow for more surface contact, reducing the time needed to heat and fuse the pipe. Socket fusion joins pipe and fittings together, rather than simply joining pipe to pipe. It requires less pressure than butt-welding and is more commonly used on smaller sizes of pipe (4″ or less). Socket welding has additional advantages of requiring less machinery and is more portable than the heavier equipment required for butt fusion.

Pipefusion-Electrofusion

Electrofusion is a method of joining HDPE and other plastic pipes with special fittings that have built-in resistive wire which is used to weld the joint together. The pipes to be joined are trimmed, cleaned, inserted into the electrofusion fitting (with a temporary clamp if required) and a voltage (typically 40V) is applied using a device called an electrofusion processor. The processor controls how much voltage is applied, and for how long, depending on the fitting in use. As current is applied to the resistive wire, the coils heat up and melt the inside of the fitting and the outside of the pipe wall which weld together producing a very strong homogeneous joint. The assembly is then left to cool for a specified time. The joints produced tend to be more reliable than threaded fittings sealed with O-rings.

Pipefusion-Sidewall Fusion

Sidewall (or Saddle) fusion is, like butt fusion and socket fusion, another process based on hot plate welding. Sidewall fusion differs from either socket, or butt fusion methods by performing fusion into the side of the pipe wall in a transverse orientation to the main pipe, rather than in line with the pipe. Sidewall fusion is typically employed in conjunction with either socket or butt fusion methods as a complementary process and many fusion machines designed for butt fusion are also equipped for sidewall fusion. Adaptor plates that match the outside diameter of the main pipe are applied to the heating plate to perform this type of fusion.

Mechanical Fittings

In your daily work you may encounter old pipes of different materials in the ground. You will need to connect these with new pipe materials and preferably have a restraint joint. Well known jointing methods, such as collars, flanging, welding and the use of thrust blocks can be very time consuming. Would you prefer to work fast and reduce costs? The reliable MULTI/JOINT® 3000 Plus system is your answer! Wide range fittings allow you to quickly make a restraint connection between all pipe materials, without special tools!