PipingSolutions, Inc. services

PipingSolutions - Piping Flexibility and Stress Analysis Consulting Service

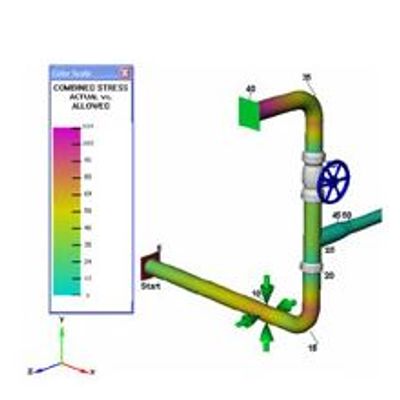

Our piping stress analysis consulting service consists of: 1.) collecting field data, if required, 2.) generating piping isometrics, if required, 3.) constructing a TRIFLEX® computer model of the piping system along with any connected equipment and 4.) processing analyses with the appropriate loading conditions.

PipingSolutions - Rotating Equipment Loading Studies Services

Casing and Nozzle Loading Studies are performed by PipingSolutions to determine compliance with NEMA Std. for Steam Turbines, API Std. 617 for centrifugal compressors and API Std. 610 for centrifugal pumps. Based upon discussions with our clients, PipingSolutions then processes additional analyses incorporating the appropriate piping and restraint modifications. The end results that we deliver are piping systems that apply loads on rotating equipment that are within the allowable limits of the appropriate rotating equipment standard.

PipingSolutions - Piping Code Compliance Stress Analysis Studies Services

Piping systems operating at very high or very low temperatures are generally difficult to design so that the stress levels are within the stress allowable limits set forth within the appropriate piping code. PipingSolutions’ staff model and perform the appropriate analyses and identify overstressed areas within piping systems. Once overstressed conditions are identified, PipingSolutions’ staff modifies the piping system configuration and or the restraints in order to achieve piping systems operating within the stress limits that are defined in the applicable piping code.

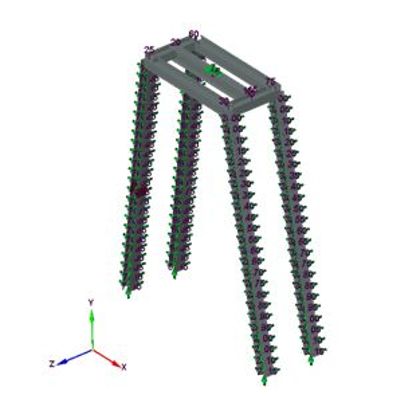

PipingSolutions - Structural Analysis and Design Services

Constructs structural models using TRIFLEX® and other structural programs to compute deflections, rotations, forces, moments and stresses in steel structures accordance with the AISC standard.

PipingSolutions - Pipe Hanger Assessment Services

Piping movements and loads can be verified in the shut down and operating conditions. Replacement pipe hangers and restraints can also be designed. Detailed reports of findings are provided to the client at the conclusion of the project.

PipingSolutions - Piping Data Collection and Isometric Generation Services

PipingSolutions: Sends it staff into the plant or industrial location to collect the required descriptive information and dimensions. Generates isometric drawings with complete bills of materials.

PipingSolutions - Flare Header Piping System Rating and Design Services

This service consists of modeling an existing or new emergency relief system including pressure relief valves and knock-out drums on the TRI*HEADER computer program. The piping system will then be evaluated by simulating a variety of blow down or relieving cases. Flow problems will be identify and a variety of possible flow solutions can be tested in the computer model to identify the optimum solution. The TRI*HEADER software used by PipingSolutions has a well-tested data base that is used to perform rigorous VLE, heat transfer and two phase flow calculations in order to accurately predict fluid behavior throughout the emergency relief system. Thermal effects are taken into consideration and choked flow conditions are identified and located. PipingSolutions can analyze existing piping networks for problem areas or we can optimize piping networks solving for minimum pipe sizes necessary to meet flow requirements.

PipingSolutions - Nozzle Stress Analysis and Design Services

This service consists of modeling a branch connection or a structural attachment on a piping system, pressure vessel, heat exchanger or tank. Our staff would utilize the applicable calculation techniques set forth in the Welding Research Council Bulletins No. 107 and/or No. 297. These WRC Bulletins are referenced in the ASME Section VIII Boiler and Pressure Vessel Code. A detailed report of our findings and recommendations is provided for each nozzle stress calculation performed by PipingSolutions.