- Home

- Companies

- Procemex Oy Ltd

- Products

Procemex Oy Ltd products

Smart Cameras

Model Procemex Flex IR - Thermal Smart Camera

High definition, fast and extremely easy smart camera to integrate with any existing Procemex OnePlatform system giving it temperature and moisture measurement capabilities. The infrared thermal camera is suitable for inspecting and filming all pulp and paper grades and printed products with 640×480 pixel resolution. Procemex FlexIR Thermal camera features 640×480 pixel resolution and 25/30 frames per second imaging frequency. The micro-bolometer wavelength is 8-12 µm and thermal imaging area ranges from -15°C to +200°C. The new infrared camera has been specifically designed by Procemex engineers to integrate seamlessly into the existing Procemex OnePlatform installed base and meet the troubleshooting and machine optimization demands of fast running paper, tissue and board machines. The infrared lens on the front end integrates with Procemex Flex camera back-end processing allowing the camera to be immediately recognized by the OnePlatform system.

Procemex Crystal Smart Camera 12 MPix 700 MHz Color

High definition, fast and extremely light sensitive camera suitable for inspecting and filming all pulp and paper grades and printed products with 4096×3072 pixel resolution. Procemex Crystal Color camera with 700 MHz data processing features 12 MPix resolution and astonishingly high shutter speeds that form a basis for premium performance class for all inspection and monitoring applications. The new camera has been specifically designed by Procemex engineers in Finland and in Japan to meet the demands of color web inspection of fast running paper and board machines. As each color channel is processed separately, a higher data processing capacity is needed. Color camera with high data processing capacity is also beneficial in over 10 MPix web monitoring camera resolutions at 50 or 60 frames per second.

Carbon Fiber Web Inspection Frames

3D Web Inspection

One-profile measurement geometry for detecting and classifying all surface defects keeping focus on dents and elevated defects The 3D web inspection is performed typically having paper against supporting roll. This geometry enables to detect very small dents and elevated defects in a very high accuracy. It is based on around 10 degree illumination angle and 90 degree camera viewing angle and can detect all other surface defects on standard paper and board machines. The resolution is typically 0.1×0.1mm requiring above 600 Mhz data processing on a 1000 m/min machine. This enables to detect elevated defects starting from 100 um. The detection of dents and elevated defects requires a special algorithm developed by Procemex in collaboration with leading Scandinavian liquid packaging board producers.

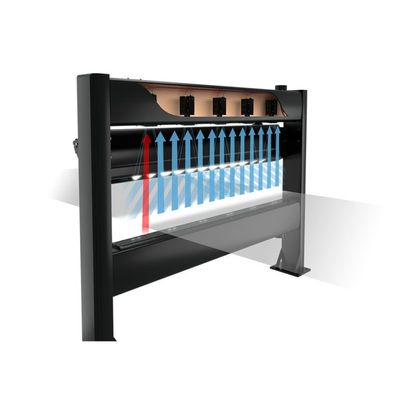

Crossed (30 degree) Side Light Web Inspection

Two-profile measurement geometry for detecting and classifying all defects focusing on surface wrinkles and de-formation. Crossed side light geometry is often combined with transmission measurement geometry. This geometry enables to detect very small wrinkles and surface de-formation by creating a shadow from side direction. The illumination angle is very low in order to be able to provide adequate shadow effect. As the light frame shifts in side direction approximately 700 mm due to light frame distance to the paper web, the crossed side light was invented and patented in order to illuminate front side from back side and vice versa. This enables to position frames within machine columns and there is no need to find a place for a light frame sticking 1000 mm out from machine frame.