Procesni Inzeniring products

Industrial Ovens

Chamber Oven Bellow 600°

Chamber oven for heating products loaded on carts. “For heating products to the prescribed temperature. Air flow ventilation. Mineral wool. Double ceilings and walls.” Intended to heat products to the prescribed temperature. The evenness of products can be achieved through mixing the oven atmosphere with the air flow vents. Heating time depends on the material demands, they are the basis for determining the size of ventilators and gas burners. Ovens are insulated using mineral wool to prevent heat loss. They are equipped with a double ceiling and walls ensuring proper air circulation. The supply and return air ducts have temperature sensors built-in for each zone.

Industrial Dryers

Chamber Dryer

“For your smaller series. For your limited edition products, tests or individual production. For a better quality, control and your smaller scraps. CHAMBER DRYER” In a chamber dryer we dry either smaller, limited edition products that differ from others in the large-scale production or pieces from individual production. They are also used to dry concrete products and can be used as lab dryers in tests prior to serial production. A chamber dryer is made up of a chamber entailing an air duct channel with an air flow vent, gas burner, door, outlet channel, fresh air supply, moisture inlet and an electrical enclosure with a panel.

Continuous Dryer

“Conveyor dryers, rotary dryers, dryers with transport chains, and transport carts.” In continuous dryers the material travels through the dryers made up of several zones; in each zone several different physical and chemical processes take place. The dryers differ with regard to the manner the products are transported through the dryer: conveyor belt, transport chains, transport carts or rotary pumps. “Achieving even material dryness through strict parameter control in the dryer.” As the goal in the initial zones of the dryer is to raise the product temperature, a high level of moisture of the air circulating around the product is necessary. This increases the diffusion in the product interior onto the surface. In the further zones, the level of moisture in the circulating air increases – as a result the diffusion from the product surface into the air increases as well.

Oxidation Devices

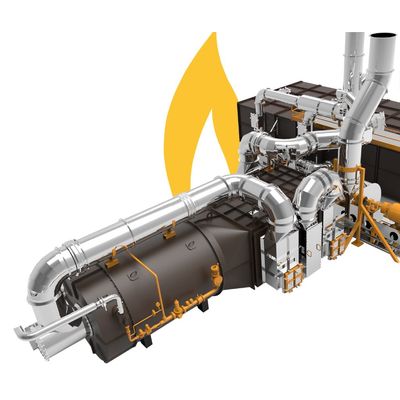

Oxidation Chamber

Has the task of “mixing” the organic emissions, air and the combustion source and to maintain the oxidation process. Organic emissions can combust stably into non-harmful by-products only under certain conditions that limit the combustion levels. Simply put: the only way to clean the air is to give the emissions enough oxygen, the necessary combustion temperature and retention time. In constructing the oxidation chamber we thus always pay special attention in constructing the combustion head, which is in fact a mixing station. The mixing process depends on the concentration and types of solvents: whether air or oxygen need to be added, whether central or side burners are used, and on the type of insulation required. Hard insulation results in the accumulation of more heat and enables an additional ignition when the reacting agents come in contact with the incandescent insulation. It also allows for greater speeds of nearby gases.