Progress Eco S.A. products

Wedge Wire Screens

Progress - Wedge Wire Screen - Square Opening

Wedge wire screens with square openings are manufactured from HT, GZ, Sa, Sb, Sba and D type round and profile wires.

Progress - Wedge Wire Screens - Rectangular Openings

Wedge wire screens from profile wires are manufactured from HT, GZ, Sa, Sb, Sba and D type profile wires.

Progress Eco Pro-Slot - Wedge Wire Inserts for Sieve Bends

Inserts made from Pro-SLOT® wedge wire screens are highly effective in filtration and separation processes for solid and liquid particles, including applications such as process water and industrial wastewater treatment, water purification, and sugar and starch production.

We supply wedge wire inserts for both gravity-fed and pressure-type sieve bends. Additional reinforcements, fittings, and customized profile wire inclinations are available upon request.

Progress Eco Pro-Slot - Rotary Screens and Inserts for Drum Screens

The high open area ratio of Pro-SLOT® wedge wire screens ensures excellent throughput of rotary cylinders. This allows for increased efficiency in processes such as process water and industrial wastewater treatment. The self-cleaning effect of the screen significantly reduces operating costs. We supply inserts for drum screens with both internal and external inflow configurations.

Progress Eco Pro-Slot - Wedge Wire Inserts and Baskets for Screw Presses

We offer inserts for screw presses and separators made from Pro-SLOT® wedge wire cylinders. Thanks to their high manufacturing precision and excellent load-bearing capacity, they perform exceptionally well in applications such as food processing, brewing, recycling, the wood industry, and agriculture. Our solutions are supplied to leading screw press manufacturers, including FAN Separator, Agrikomp, Cri-Man, and PFTechnology.

Progress Eco Pro-Slot - Wedge Wire Filter Elements and Inserts

We design and manufacture specialized inserts for filtration and separation processes of solid and liquid media, suitable for both pressure and non-pressure filters and equipment. To model optimal solutions, we use advanced design software and applications.

Progress Eco Pro-Slot - Filtration Tubes with Slots from 10 µm

Custom-made Pro-SLOT® wedge wire tubes can enhance precision and optimize filtration processes. Our production program covers all tube types used in mechanical filtration, from outside to inside (FOTI) and from inside to outside (FITO), with slot sizes starting from 10 microns and working profiles ranging from Sb6 to Sb70.

Pro-Slot Wedge Wire Screens

Progress Eco Pro-Slot - Wedge Wire Screens & Tubes

Welded Pro-SLOT® slotted sieves are the main and the most technologically advanced line of our products. They are reliable for using in numerous filtration processes for solid and liquid particles. We manufacture them from profiled wires of high quality stainless and acid-proof steel. The technology of electrofusion used for joining profiled wires for a set of supporting rods lets us obtain extremely precise dimensions of apertures. They work extremely well both in static structures, as well as dynamic ones, providing optimal effectiveness of a process even in tough and aggressive work environment. Depending on individual applications, our company offers flat welded or round welded sieves of different size and shape, types of fittings, with a possibility to join individual elements into larger segments.

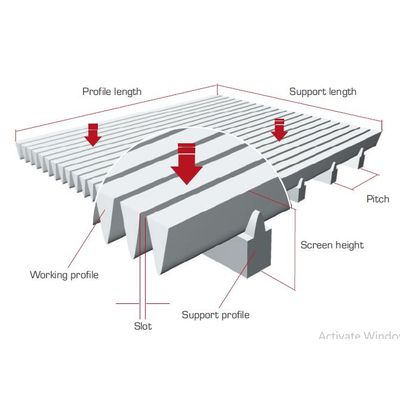

Progress Eco Pro-Slot - Flat Panels of Wedge Wire Screens

Flat panels of wedge wire screens are manufactured by welding special profiled working wires to support wires at an angle of 90 degrees. A precise slot is received by means of applying modern welding technology between working wires and support wires. The result is a rigid screen construction with the capability of withstanding heavy loads.

Progress Eco Pro-Slot - Cylindrical Wedge Wire Screens

Cylindrical screens are received by simultaneously winding a spiral of profiled working wire and welding them to support wires, which are arranged along the axis of the cylindrical construction. This technology allows to provide welded profile wire screens for applications where high precision of the screen together with high strength is required.