Promill products

Technologies and Services

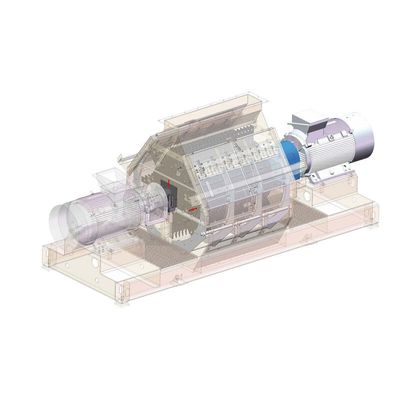

Promill - Hammer Mills

The principle of the mills is to reduce the dimensions of incoming materials to a particle size sought after by the mechanical action of hammers coming into contact with the material. The material thus reduced is conveyed through calibrated screens until the next step of the transformation process. PROMILL has a wide range of hammer mills to offer solutions to all industries and customers. The design of the PROMILL hammer mills guarantees the required quality and capacity while optimizing the durability of the components.

Promill - Model WCR - Wet Hammer Mill

This type of grinder is mainly used for the wood industry and for the grinding of plant materials in the post-drying phase. The moisture content in the material to be crushed is quite high and therefore requires a better grinding torque and an increased strength of the components. Different powers of motorization are available according to the capacities to be reached.

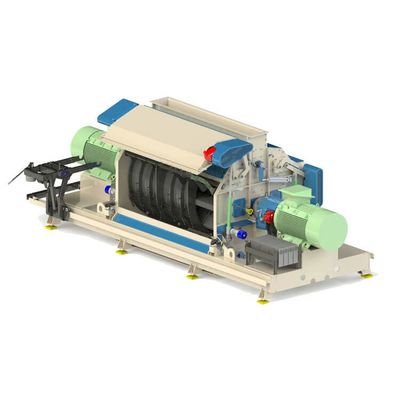

Promill - Model Type BNA - Hammer Mill Refiner

The BNA mill is used to carry out the final step of reduction of the particles sizes also called “refining”. The incoming material was previously dried to contain only 8-12% moisture. The desired particle size is obtained at the outlet of the sizing screens. Different crusher / refiner sizes are available depending on the materials and production capacities to be produced. Different powers of motorization are available according to the capacities to be reached.

Promill - Model Type BNE - Bulk Grinding Mill

Different uses are made of rendering products. BNE grinders have been developed to handle all types of complex materials requiring high abrasion resistance.