Proses Makina Company products

Mining -Conveying

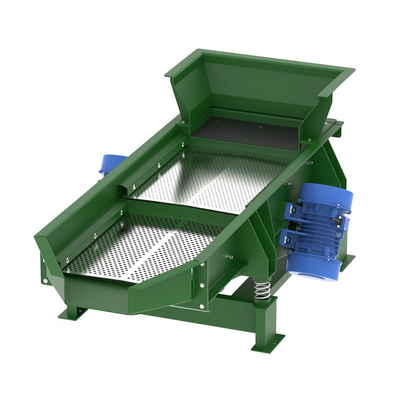

Proses Makina - Vibrating Feeder

The vibrating feeder incorporates key elements that enhance its performance under demanding operating conditions. The unit features a motor-driven vibrator mechanism that imparts controlled oscillations to a trough, ensuring uniform material flow.

Proses Makina - Heavy-Duty Flow Apron Feeder

An apron feeder is a type of heavy-duty conveyor used in mining and material handling operations to transport large bulk materials. It consists of a series of overlapping metal plates (or pans) mounted on chains, which move along a set of rollers. Apron feeders are designed to handle high-impact loads and can operate in harsh environments, making them ideal for feeding crushers, screens, and conveyors in mining, quarrying, and other heavy industries.

Mining - Crushing

Proses Makina - Cone Crusher

Cone Crusher is a versatile and efficient crushing solution designed for the reduction of various materials in mining and aggregate industries. Featuring a cone-shaped crushing chamber, the crusher ensures uniform particle size distribution, optimizing downstream processes. The hydraulic system provides precise control over the crusher settings, allowing for adjustments to accommodate different feed materials and achieve desired product sizes.

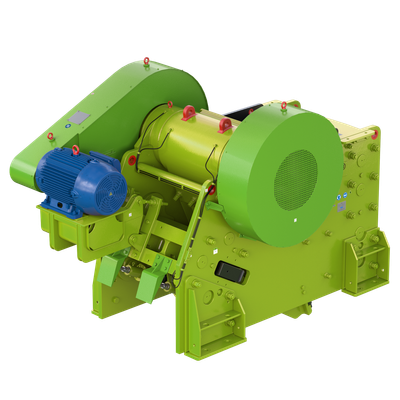

Proses Makina - Jaw Crusher

Proses Makina’s Jaw Crusher is a leader in ore processing machinery, featuring a robust design that effectively breaks down hard and abrasive materials. Utilizing the principle of compression, this machine applies force on the feed material between a fixed and a moving jaw. This process yields high-quality crushed material, making it exceptionally suitable for mining and mineral processing applications.

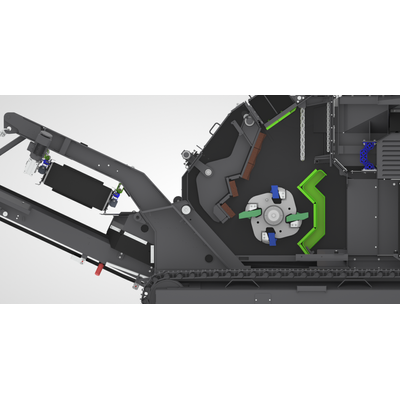

Proses Makina - Impact Crusher

Impact Crusher is a robust and efficient crushing solution, designed for the reduction of various materials in mining and construction applications. The crusher utilizes a high-speed impact force to break down materials, ensuring a uniform particle size distribution. Featuring adjustable settings and a durable design, Proses Makina`s Impact Crusher provides flexibility and reliability in crushing operations. With its advanced technology, the crusher offers efficient energy utilization and high throughput.

Metal Recycling & Refining - PGM Refining Systems

Proses Makina - Chemical Refining System

Proses Makina PGM Refining System is used to separate platinum, palladium, and rhodium which are the most important metals in terms of major commercial significance from spent catalysts, end of life catalytic converters or metal alloys. PGMs consist of six chemically similar elements, sometimes further classified into light which are ruthenium (Ru), rhodium (Rh) and palladium (Pd) and heavy iridium (Ir), osmium (Os) and platinum (Pt). They are highly demanded metals because of common use in today’s key technologies which are catalysis, electronics, and fuel cells.

Proses Makina - Induction Furnace

The Induction Furnace is an electric furnace that applies heat through the induction heating of metal. Using the principle of electromagnetic induction, the furnace delivers rapid and direct energy transfer to the material, enabling controlled and uniform melting across a wide range of metal types and batch sizes. These furnaces can be designed in various capacities and can be used to melt iron and steel, copper, aluminum, PGMs, and precious metals.

Metal Recycling & Refining - Gold Refining Systems

Proses Makina - Electrolysis & Electrowinning Systems

Electrochemical techniques are essential in a wide range of industrial applications, serving as core processes for the extraction and purification of metals. Electrolysis is a process that drives a non-spontaneous chemical reaction by applying an electric current. In this process, an electric current is passed through an electrolyte, resulting in the decomposition of the compound. Specifically, electrolysis utilizes a specialized electrolytic cell, where gold or silver ions are reduced and deposited onto the cathode, while impurities remain dissolved in the electrolyte solution.

Metal Recycling & Refining - Battery Recycling Systems

Proses Makina - Shredder System

Proses Makina introduces its latest innovation in battery recycling technology: advanced Shredder Systems specifically designed for the mechanical processing of various battery types. Engineered with a strong focus on efficiency, safety, and sustainability, these shredders are set to transform battery recycling operations worldwide.

Proses Makina - Vacuum Dryer System

Vacuum drying is essential in battery recycling to ensure the safe and efficient processing of battery components. Removing moisture and volatile compounds is crucial for preventing chemical reactions, potential hazards, and contamination during further processing stages. The drying process in battery recycling, conducted under vacuum conditions, is a crucial step that aims to remove moisture and other volatile substances from battery components. This process is especially important in recycling lithium-ion batteries, as they contain electrolyte solutions that need to be removed before further processing. By conducting the drying process under vacuum conditions, the boiling points of liquids are lowered, which means that the drying can occur at lower temperatures than traditional drying methods.