- Home

- Companies

- Protherm Furnaces

- Products

Protherm Furnaces products

Chamber Furnaces

Protherm - Model ECO Series - Chamber Furnaces

ECO series have been designed for professionals as an economical solution. With brick and fiber insulation elements, these models can be optimally used for your general procedures. ECO series furnaces are designed to operate at 1100°C, all of which have front loading for easy operation and unique internal construction to maintain a cooler outer case. Important advantage of the model is that change ıf the quartz glass protected element is very easy and economic. Typical applications for the product is melting, thermal ageing, ceramics sintering, metal heat treatment, chemical decomposition and thermal shock testing.

Tube Furnaces

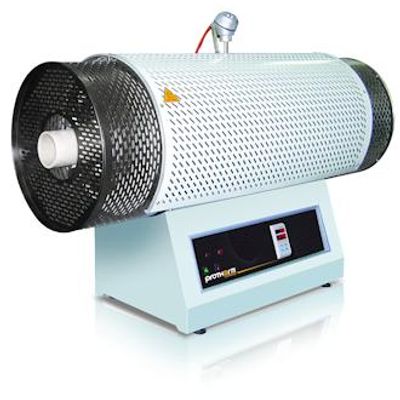

Protherm - Model PTF Series - Tube Furnaces

PTF series tube furnaces are tube furnaces that could be used when laboratory experimentation is performed horizontally, vertically, or at specific angles. Configuration of the tilt angle, and the stable temperature environment make these furnaces suitable for many possible processes. Standard PTF series furnaces cover a range from 1100°C to 1600°C, using wire and SiC heating elements for processes. SiC heating rods installed parallel to the working tube ensuring perfect temperature uniformity and easy replacement.

Dental Furnaces

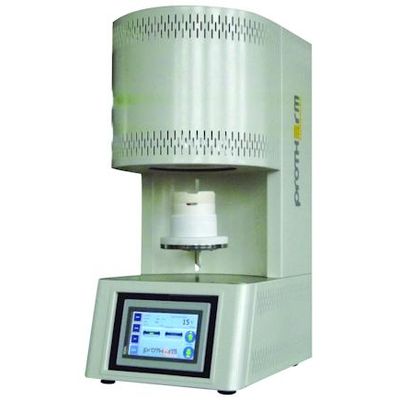

PROTHERM - Model ELV MOS Series - Dental Furnaces

ELV MOS series is designed for bottom loading operations and for quick charging and discharging procedures in laboratories. Available with brick and fiber insulation elements, with a wide variety of options, ELV MOS series is designed especially for dental applications. Standard ELV MOS series furnaces cover a range of temperatures up to 1600°C, all of which have dual skin housing for low external temperatures and high inner temperature stability uniformity.

High Temperature Furnaces

Protherm - Model ELV Series - Elevator Furnaces

The ELV Series Elevator Furnaces by Alser Teknik Seramik A.Ş. represent high-performance, elevated heating solutions tailored for rigorous industrial applications. These furnaces are engineered to achieve high-temperature environments essential for processes such as material sintering, ceramic firing, and metal annealing. With precise temperature control systems, these furnaces ensure consistent and uniform heating, crucial for achieving optimal treatment outcomes. The advanced elevator mechanism is designed for easy loading and unloading, enhancing operational efficiency. Built with robust materials, the ELV Series furnaces promise durability and longevity, even under continuous high-stress conditions. Optional features include advanced atmospheric controls, customizable chamber sizes, and enhanced safety systems, making them adaptable to a variety of high-demand production environments.

Protherm - Model HLF Series - Heat Treatment Furnaces

Available with brick and fiber insulation elements, with a wide variety of options, HLF series is the optimum choice for general heat treatment procedures. Used by many professionals and craftsman for many years, standard HLF series furnaces cover a range up to 1200°C, and have a volume of 1000 liters. However we do provide a much larger range for our customers on request with customized models. Galvanized coating covered epoxy painted structure, providing longer life time and aesthetics.