Proventia products

Emissions Control - Retrofit Emission Control

Proventia - Model NOxBUSTER - City - High NOx Reductions in City Driving

Proventia NOxBUSTER® City DPF + SCR is an emission control system that can be retrofitted to heavy vehicles already used in traffic like buses, coaches, refuse collection vehicles and trucks. NOxBUSTER® City reduces emissions up to Euro VI emission level.

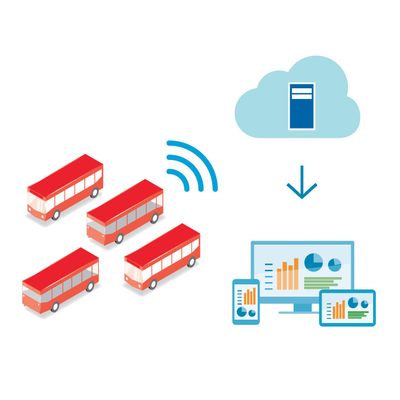

Proventia - Model PROCARE - Drive In-Service Monitoring System

Proventia PROCARE™ Drive is an optional telematics solution for continuous monitoring of the NOxBUSTER® City system operation and emission reduction performance. PROCARE™ Drive is a web-based tool for monitoring vehicles` exhaust aftertreatment systems – and especially SCR and NOx reduction performance. PROCARE™ Drive provides information about exhaust gas temperatures and back pressure data, AdBlue® level, temperature and dosing rate. It provides automated DPF and SCR alerts concerning possible maintenance requirements. Proventia PROCARE™ Drive is a compact device that will help fleet operators minimise the risks associated with vehicle exhaust systems, and improve emission monitoring and reporting. All collected data is automatically transferred to customer-specific cloud storage, where data can easily be exported for reporting to the authorities, for example.

Proventia - Model NOxBUSTER - City NOx Reduction Retrofit System

Proventia offers proven solutions for ULEZ and CAZ NOx reduction retrofit programs. The Proventia NOxBUSTER® City is a retrofit solution for ULEZ and CAZ, which enables Euro III, IV or V buses and trucks to meet Euro VI emission standards. The systems have full TfL and CVRAS approval ensuring compliance with the Ultra Low Emission Zone (ULEZ) and Clean Air Zones across the UK. Over 1,400 systems have been installed across all major London bus operators.

Proventia - Model SuperTornado - Urea Mixing Technology

Proventia SuperTornado™ urea mixing technology is a flexible platform that can be used with various urea dosing systems to solve deposit problems and improve SCR performance in many applications with different engine sizes and in a variety of operating environments. The Proventia SuperTornado™ enables the design of compact EAT systems for applications with limited space requirements. The system can be integrated with DPF substrates if the chosen emission strategy requires DPF.

Exhaust Aftertreatment Systems

Increasingly stringent emission standards are driving engineers to develop top-performing exhaust aftertreatment systems (EAT systems) that are not only compliant with future emission standards but also fit into minimal spaces. Proventia provides full-scale emission knowhow and expertise in integration. We provide selective catalytic reduction (SCR), diesel particulate filter (DPF), diesel oxidation catalyt (DOC), urea/ AdBlue/ DEF mixing technologies and components integrated into a fully tailored system to meet present and future Euro, Stage and Tier standards.

Proventia SuperTornado - Urea Mixing Technology

SCR technology uses ammonia in the form of a urea-water solution (DEF/ AdBlue) as a reducing agent for catalytic reactions. Particularly if an airless injector is used, the urea solution has a tendency to form deposits (urea crystallization) in the process of evaporation and decomposition into ammonia. To prevent the build-up of deposits and to obtain good uniformity in the catalyst cell, an efficient mixer is needed. Particularly in limited-space applications and in real driving cycles that include slow driving with low loads, the high NOx reduction targets of today´s regulations cannot be reached without efficient urea mixing. The key to solving mixing problems is to have an effective urea mixer, such as the Proventia SuperTornado.

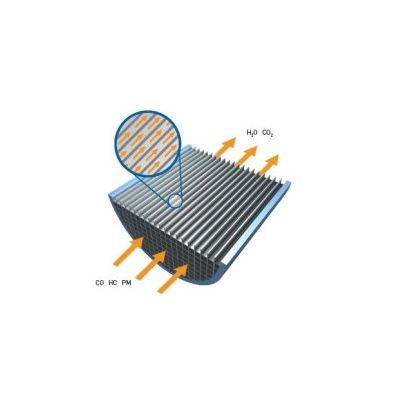

DPF & DOC Technologies

Proventia technology offering includes also diesel particulate filter (DPF) and diesel oxidation catalyst (DOC) technologies to reduce particulate matter (PM) and carbon monoxides (CO) and hydrocarbons (HC) from exhaust gas. Our DPF and DOC knowhow based on over 20 years of experience of DPF and DOC technologies and their usage in on- and non-road applications. Upcoming Stage 5 emission standard, due to be implemented in 2019-2020, simply means that DPF and SCR technologies will be mandatory in 56-560 kW engines, and possibly also DOC technology will be included. This arrangement calls for not only expertise of all emission control technologies, but also integrating and optimising skills that will quarantee the optimal emission reduction perfomance in each application.