Pure Water Technology LLC products

Reverse Osmosis Systems

Skid Mounted Reverse Osmosis System

Pure Water Technology manufactures Commercial Duty Brackish and Seawater Desalination Systems to provide potable water for communities, hotels, industrial applications, resorts, ships, barges, condominium complexes oil drilling platforms, and many other land based and marine applications. The units include multimedia filters, 20 and 5 micron cartridge or bag filters, reverse osmosis unit, automatic backwash system, membrane cleaning system and crating. The highest quality components have been selected for the rugged duty that will be required for the water purification applications.Modifications of these larger systems are available on request to accommodate individual customer needs for space available and special applications.

Containerized Mobile Reverse Osmosis System

40 or 20 Ft. high-cube ISO container with double cargo doors on one end, roll-up door on the other end and a man door on a long side. The container will include interconnecting plumbing and electrical for all enclosed equipment. Central connection point for all plumbing connections. Ceiling lighting included. Roof access panel for media filters. Container is painted with white epoxy paint inside and out.

Compact Reverse Osmosis System

Pure Water Technology offers a range of reverse osmosis seawater desalination systems. The units remove salts from seawater with salinity up to 45,000 ppm TDS water as found in the Mid-East Gulf region and produce water less than 500 ppm TDS for drinking water.

Wastewater Treatment Plants

Extended Aeration Sewage Treatment Plants

Pure Water Technology`s range of advanced wastewater treatment technologies of Membrane Bio-Reactor systems (MBR), Submerged Aerated Filter (SAF,) Extended Aeration Plants, Moving Bed Bio-Reactors (MBBR) provides high treatment efficiencies and lower foot-prints through designs that integrate processes.We are engaged in offering Wastewater Treatment Plant to our clients based across the nation. These Sewage Treatment Plants are designed by our team of experts who uses the following technologies:

Membrane Bioreactor (MBR)

Sewage treatment plants that employ the Membrane Bio-Reactor (MBR) process are the systems of choice where the production of high quality water effluent is an advantage. MBR processes are therefore ideal for re-use applications, whereby the treated effluent is used for irrigation, watering or wash-down uses. MBR Technologies use a bank of membranes that are either immersed in the final effluent tank or are immersed in a separate side-arm tank to filter out biological solids as a final stage in the STP processes. The result is that MBR plants provide a high purity effluent. A Chlorination storage tank is usually incorporated into the process design to ensure that the water produced can be stored safely. The MBR process also operates at high sludge levels, so less sludge volume is required to be treated or transported off-site.

Submerged Aerated Filter

Within the wastewater industry (SAF) Submerged Aerated Filter Technology is seen as the simplest and most cost effective method of commercial and residential sewage sanitation / waste water treatment, particularly for small to medium sized treatment plants where available land is limited, and where full time operational manning would be uneconomical. The SAF could be described as a “box of media”. It utilizes a rigid, corrugated, structured polypropylene media to give a high surface area for biomass attachment (200 ft2 per ft3). The media is arranged into cells-in-series where effluent is contacted with the fully submerged media in the presence of co-current aeration. Air enters the process below the media via fine bubble membrane diffusers, a secondary clarifier tank follows the SAF for removal of any biomass that sloughs off the media during operation.

Moving Bed Bioreactor Plants (MBBR)

With extremely short retention time meets client’s objectives and consistently, meets strict effluent requirements once in operation. This innovative fixed-film moving bed process uses thousands of special suspended biomass carriers designed to create a large total surface area for bio film growth –enhancing the biological wastewater treatment process without increasing the plant footprint. The MBBR is ideal for handling the organic loads in both food industry wastewater and domestic wastewater. MBBR technology is based on the bio-film principle with an active bio-film growing on small specially designed plastic carriers that are kept suspended in the reactor. The carriers are designed to provide a large protected surface area for the bio-film and optimal conditions for the bacteria culture when the carriers are suspended in water.

Deionizer Control Systems

Deionizer Control Systems

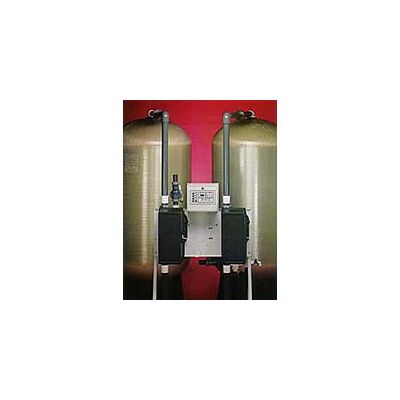

An economical alternative to rental exchange deionization (DI), the Osmonics Autotrol series 730 control provides dependable, semi-automatic performance in lighter duty applications.Depending on your type of use and the quality of your influent water, the series 730 control can lower your cost of deionized water by as much as one-half when compared with the cost of exchange service.Features such as automatic shutoff in case of power failure, and check valves to prevent the accidental flow of water into the regenerant containers, add to the 730 control`s performance appeal. And, the unit`s specially adapted valves, electronics, meters, piping and fittings all come preassembled for quick, easy installation.

Deionizer Control Systems

Engineered for medium-sized deionization (DI) applications, these dependable units feature the same precision electronics and performance characteristics as their large-scale counterparts, all in a smaller, top-mounted package. Applications cover the full spectrum of industrial, commercial, medical and agricultural users. The 168 valve gives Osmonics Autotrol 7700 series controls improved performance characteristics.

Deionizer Control Systems

Designed and built for maximum deionization (DI) demands, these high-capacity controls can easily handle the heaviest requirements of manufacturing and medical applications, as well as those of large-scale commercial users such as printing or food processing plants, electroplating or metal finishing facilities and high-volume car and truck wash installations.