Rawlings Manufacturing, Inc. products

Vertical Hog Models

Rawlings Wood Hog - Model 4872 - PXZ - Vertical Feed Hog Processing Debarker Waste System

Rawlings 4872 Vertical Feed Hog processing debarker waste at 90 tons per Hour with a single 600 HP motor. Hog Upper Case is clam shell opening to allow easy access to full rotor for ease of maintenance. Watch for our “Old School” Vibration test with the Nickel on hog base . Each machine is equipped with the Rawlings Super Hi-Inertia Solid Steel Rotor. With the increased inertia of the solid steel rotor our machine runs at lower RPM’S than our competitors resulting in overall savings of electricity and maintenance costs. Rawlings wood Hogs offers a complete line up of seven different sizes of both vertical and horizontal hogs to fit any application.

Rawlings Wood Hog - Model VRM Super XI - Vertical Feed Rear Maintenance

Introducing the “VRM” Super XI Vertical Rear Maintenance Wood Hog from Rawlings Manufacturing Inc. No cookie cutter machine can meet everyone’s space constraints or challenges. We have had several customers over the years that wanted a Rawlings solid rotary hog but did not have the overhead clearance in their existing footprint to allow for a clam shell opening type of machine. The VRM hog opens hydraulically from the rear of the machine allowing full access to the hog’s internal wear components and rotor for ease of maintenance. All Rawlings Hogs are equipped with our Patented Super Hi-Inertia Rotor that powers through feed surges with ease while still running at lower RPMs than all other machines on the market. This saves our customers both maintenance and electricity costs.

Horizontal Wood Grinder

Rawlings - Model 460 - HZX - Horizontal Wood Waste Grinder

Rawlings 460 Horizontal Feed Hog processing wood waste with twin 300 Horsepower motors for a industrial Mulch bagging operation. This system is complete with a receiving conveyor, belt in-feed and vibratory out-feed conveyor, metal detector, work platform and Rawlings Horizontal grinder. Each unit is equipped with the Rawlings Super Hi-Inertia™ Solid Steel Rotor. With the increased inertia of the solid steel rotor our machine runs at lower RPM’S than our competitors resulting in overall savings of electricity and maintenance costs.

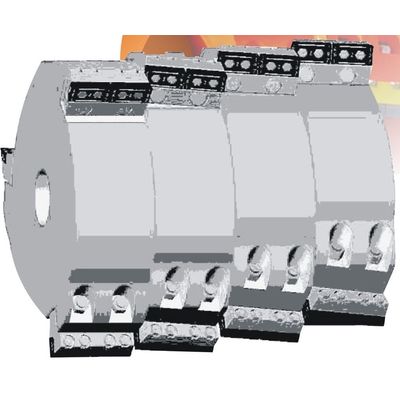

Super Hi-Inertia Rotor

Super Hi-Inertia - Solid Steel Rotor

The Rawlings rotor is designed to maximize inertia while minimizing its weight. With the increase of inertia our machine runs at lower RPM’S than our competitor’s machines and half the speed of conventional hammer mills resulting in overall savings of electricity and maintenance costs. The cam profile of the Rawlings rotor prevent feed surges by keeping material closer to the cutting edge of the bits. This translates to better productivity as the in-feed conveyor is stalled less frequently and less down time as the increased energy reduces the number of motor drive stalls.

Others

Rawlings - Industrial Sized Wood Grinding Stationary System

Rawlings specialty is custom designed industrial sized wood grinding systems . Rawlings wood hogs comes in all shapes and sizes, we offer a complete line up of 7 different sizes . We offer both vertical and horizontal models to fit any application; from simple stand-alone Vertical Hogs, to complete multi-dimensional Horizontal grinding systems. Add a wide variety of available options, and you’ve got the flexibility to customize the perfect wood recovery system.

Rawlings - Portable Wood Grinders

Rawlings Portable Wood Grinders are heavy duty portable grinders that are capable of producing valuable wood fiber products in a single pass. These high performance portable wood waste recovery systems allows our customers full grinding capabilities at lower operation costs. The Rawlings HZX Horizontal is a heavy duty wood hog that can process material of any length to the customers exact specifications. Units are available with tracks, skid mounted, tires, diesel, or electric powered.

Rawlings - Rotary Disc Screen

A Rotary Disc Screen ahead of your hog separates acceptable sized combustible material from the oversized material. The hog then works only on oversize material, reducing its energy requirements and increasing its capacity.

Rawlings Rotor - Model Super Hi-Inertia - Retrofits

The Super Hi-Inertia Rotor provides crushing & shearing power to handle the toughest jobs. We have maximized the Inertia while maintaining a lower weight. Higher Inertia means more kinetic energy to power through surges. Please contact us for further information to Retrofit Your Existing Hog.

Rawlings - Walking Floor Storage Bin

Rawlings provides a variety of engineered solutions for handling difficult materials. Systems are built to suit and are suitable for storing, receiving and metering a variety of materials. Systems are custom engineered to your specifications, with virtually unlimited dimensions and weight restrictions. The unique design handles nearly any solid material, including biomass, solid waste and agricultural products. Energy/Fuel: Hog fuel; Biomass; Bagasse; Coal; Pellets; Pucks; Refuse Derived Fuel.

Rawlings - Rotary Mill for Mineral Waste

The Rawlings Skid Mounted Drilling Waste System. Designed to process contaminated mineral waste from drilling operations. The Rawlings unique helical striker orientation generates powerful forces with enough kinetic energy frame adjustment for striker tolerances to meet product specification, allowing full product control.