- Home

- Companies

- Remington Valve

- Products

Remington Valve products

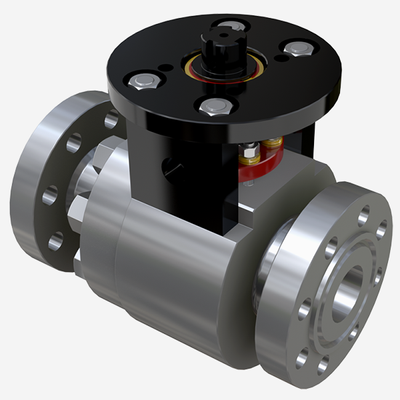

Remington - Valve for Double Block and Bleed Applications

The Remington C-Series Valve is engineered to meet demanding sealing needs in bi-directional, double block and bleed applications. Featuring a trunnion design, this valve effectively seals from both sides and is equipped with a bleed port between the blocks. Integral to its design are dual springs on the upstream and downstream seats, which press the seats firmly against the ball, ensuring a secure seal in both directions. These springs also prevent solids from accumulating behind the seats. Incorporating O-rings on the outer seat diameters allows system pressure to activate the sealing process. Available in full or reduced port options, the C-Series Valve performs optimally at temperatures up to 450 degrees Fahrenheit. This valve is particularly suitable for applications such as chemical processing, petrochemicals, and power generation, where precise isolation and robust construction are paramount.

Remington - Relief Valves for Automated Overpressure Protection

The Remington E-Series relief valves provide essential overpressure protection by serving as a preliminary pressure-reducing mechanism before the main relief valve engages. These valves can handle pressures typical of boiler systems while ensuring a secure shutoff, making them suitable for critical applications. The E-Series valves allow for customization to meet specific flow requirements without the risk of choking. They include actuation designed with safety margins for operation under extreme conditions and come with a comprehensive automated package consisting of syphon tubes, transducers, and control stations. Feedback mechanisms to a control room are standard, and individuals can program set pressure levels for optimal protection. The I-Series acts as a block valve to isolate the E-Series during maintenance, continuing the tight shutoff design of the E-Series. This design allows for servicing of silencer/exhaust or the relief valve itself while considering customer face-to-face distances and piping materials. These valves find application in industries ranging from chemical processing to power generation, providing versatile, dependable overpressure protection.