Renner Schlachthaustechnik GmbH products

Scalding and Dehairing Machines for Pre- and Subsequent Cleaning

PRE-CLEANING with the RENNER BRUSHING WASHING MACHINES. Thoroughly cleans the carcass soiled with dirt and blood. The scalding water is thereby less soiled. SCALDING with the RENNER PADDLE WHEEL TANKS is a process where the pig is automatically immersed into a tank with scalding water at approx. 60°C. DE-HAIRING is carried out with a nonsynchronous de-hairing machine by RENNER. These machines by RENNER are designed for the de-hairing of 40-200 pigs per hour.

Renner - Conveyor Technology

RENNER analyses, designs, manufactures and installs conveyor systems for a wide range of applications in slaughterhouses and boning halls. Our conveyor systems ensure efficient operation of all production and logistics processes. We supply chain conveyors, empty hook conveyors, pneumatic push rods, stacking conveyors, compressed air and vacuum conveyor systems and belt conveyors. PLC systems enable optimal control of your systems.

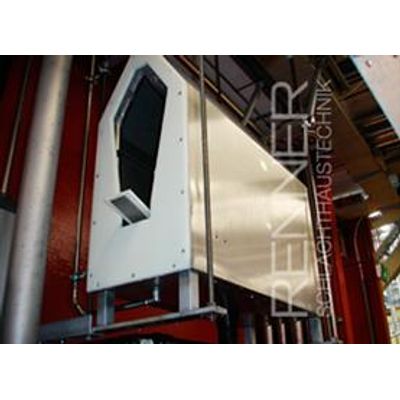

Renner - Hygiene Technology

RENNER has the ideal hygiene technology for all applications in slaughterhouses and boning plants. Our products stand for solid quality and comply 100% with the stringent hygiene regulations for the food industry.