Rodan Engineering Company Ltd. products

EFW

Rodan - Model RDF/SRF - Mmunicipal Solid Waste (MSW) Technology

Turning RDF/SRF to Power Safely. Conventional RDF/SRF production technology is used to recover the drier higher calorific fraction of municipal solid waste (MSW). This is then pelletised to form a consistent pyrolyser feedstock which is then metered into the M3RP pyrolysis retort (sealed chamber) through airlocks. Inside the retort the materail is indirectly heated to 600°C in the absence of oxygen, by a low NOx burner running off previously produced pyro-gas. The heating in the absence of oxygen causes the materials within the RDF/SRF to break down into their constituents, for example plastics de-polymerise into oil and gas.

Rodan - Model MSW - Advanced Thermal Treatment System

Operation: Delivered waste (typically unsorted MSW) is weighed in over the weighbridge. The delivered waste is tipped onto the Tipping Floor and then visually inspected for hazardous or oversize items before being loaded into one of two loading hoppers by front-end loading shovel. Any oversized wastes are shredded to a nominal 400mm prior to loading. From the hoppers the waste is conveyed up an inclined conveyor fitted with belt weighers to one of two drag-link conveyors to a set of Ram Loaders at the front end of each of the large aerobic BioDigesters. Each BioDigester can accept up to 150 tonnes per day of MSW.

Rodan - Model M3RP - Thermal Distillation/Deploymerisation Plant

The M3RP Advanced Thermal Treatment Plant is a conversion process that depolymerises and then distils waste materials into gas, oil and carbon char. It forms the basis for all the Rodan thermal energy from waste systems and consists of: An in-feed system consisting of a specially designed hopper that receives pelletised shredded feedstock. The hopper sits atop an airlock system to prevent infiltration of air/oxygen.

MRFs - Recycling Equipment

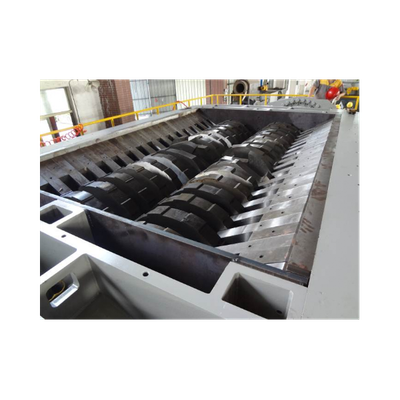

Rodan - Model GM-XM - Shredders Recycling System

This machine will cut your production time in half! The cutters in this machine are 4" thick, hot die forged and machined to finished profile from a solid alloy with patented ribbed edge. The cutters are then assembled in a precision cleaning finger frame assembly with cleaning finger cutter bars.

Rodan - Fragging Plants

20 tph car fragmentation plant: 2m wide apron conveyor feeding, 2.5m wide x 1.8m vertical shear shredder, into a 1.8m x 1.8m horizontal shredder and then into a vertical grinder and then into a vertical grinder.