- Home

- Companies

- Roper Pump Company

- Products

Roper Pump Company products

Gear & Lobe Pumps

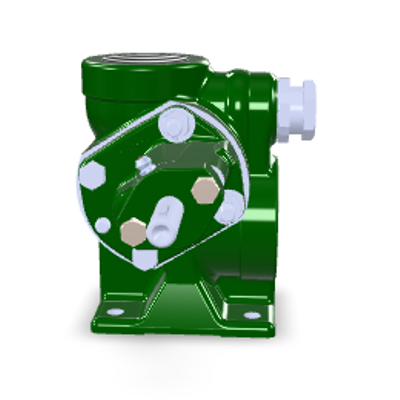

Roper - Model 2001 Type 10 - Gear Pump

Since 1958, Roper Pump Company has been involved in supplying positive displacement pumps for the lacquer injection systems in the can manufacturing process. Over the last 37 years, the units have evolved to meet the needs of the manufacturer. Roper has taken the next step with the introduction of the 2001 Type 10.

Roper - Model 2835 Series - Gear Pumps

When the going gets thick, this pump gets going. Count on it every time. The 2835 Series offers sealing flexibility with its mechanical seal or lip seal, and packing is also available. This reliable external gear design includes quiet running helical gears, and an angled gear arrangement. The enlarged ports facilitate pumping, and low horsepower requirements allow the use of lower cost motors. The 2835 Series can handle pressures up to 75 PSI and capacities up to 11.3 GPM.

Roper - Model 3600 Series - Gear Pump

3600 Series pumps operate smoothly and with equal efficiency in either direction of rotation. They effectively handle heavy, viscous materials such as asphalt, molasses, roofing compounds, resins and inks, as well as fuel oils, ethanol, saltwater, condensate and similar thin liquids. Pumps can be supplied in several materials of construction, with or without built-in relief valves.

Roper - Model 3600 EVO Series - Gear Pump

Tired of replacing pumps every season? The long-lasting 3600 EVO Pump moves high temperature and high abrasive fluids with ease so you can maximize efficiency and minimize costly down time.

Roper - Model 3632 - 3

Need more flow out of your 3″ pump? Load and unload your tanks faster. Roper Pump’s 3632 pump increases the flow rate for your 3” pump, giving you: faster tank turnover, more money in your pocket, and less time on the road.

Roper - Model eX Series - Gear Pump

A new breed of high-flow, extreme-condition Gear pump for multi-viscous and abrasive fluids has emerged.

Progressive Cavity (PC) Pumps

Roper - Model PC Elastomer Line - Conventional Progressive Cavity (PC) Pumps

Since 1972, Roper Pump Company’s Progressing Cavity Pumps have operated in wastewater applications and a broad range of industrial applications, including: environmental technology, food processing, chemical manufacturing, pulp and paper, and petroleum production. All our Progressive Cavity Pumps are backed by Roper Pumps’ expert technical support and customer service dedicated to getting the right pump at an economical price for every application.

Roper - Model XERIC - Progressive Cavity Pumps

XERIC – Redefining the standard for progressive cavity pumps; helping industry run smoother with reduced downtime and improved energy efficiency.

Roper - Model XERIC XT3 - Progressive Cavity Pumps

The XERIC Type 3 (XT3) is redefining the standard for progressive cavity pumps. This groundbreaking patent-protected progressive cavity pump significantly enhances performance and durability. Designed for both thick and thin fluids, the XT3 stands out with its improved dry-run capability and high-pressure functionality. Its modular design allows for easy installation, disassembly, and maintenance, reducing downtime and increasing uptime. The XT3 offers customizable connections like ANSI and NPT, ensuring drop-in compatibility with existing XERIC Type 2 setups, making the XT3 a versatile and reliable solution across various fluid applications.

Power Generation - Flow Dividers

Roper - Model Frame 5 - Flow Divider

Type of Flow Divider: Linear. Flow Divider Application: Naphtha and Distillate. Fuel Application: Various.