Ross Valve Mfg Co., Inc. products

Electric Valves

Ross - On / Off Electric Valve

The solenoid operated valve shall be globe (inline) or angle (90 degree) body with flanged end connections, be fully mounted, external solenoid pilot operated, with free floating piston (operated without springs, diaphragm or levers). It shall contain a single full-ported seat, with seat bore equal to size of valve. The minimum travel of the piston shall be equal to 25% of the diameter of the seat. For true alignment (to correct lateral thrust and stem binding), the piston shall be guided above and below the seat a distance equal to no less than 75% of the diameter of the seat.

Ross - Throttling Electric Valve

The flow control valve shall be globe (inline) or angle (90 degree) body with flanged end connections, be fully mounted, external solenoid pilot operated, with free floating piston (operated without springs, diaphragm or levers). It shall contain a single full-ported seat, with seat bore equal to size of valve. The minimum travel of the piston shall be equal to 25% of the diameter of the seat. For true alignment (to correct lateral thrust and stem binding), the piston shall be guided above and below the seat a distance equal to no less than 75% of the diameter of the seat.

Cone Valves

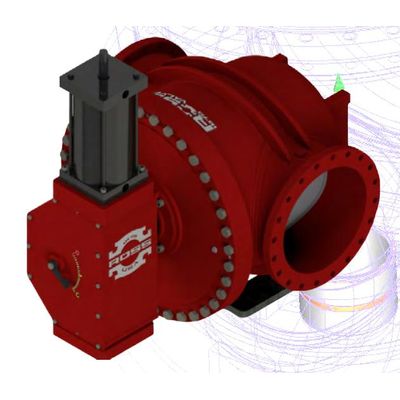

Ross - Rotary Cone Valve

Utilizing Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). Newly designed trunnion bearings with "Figure 8" grease channels (Standard). External lubrication ports for both upper and lower bushings (Standard). Modified Scotch Yoke design to enhance lift and torque capabilities (Standard). Lubrication and inspection port in valve operating mechanism (Standard). Plug position indicator pinned directly to operating shaft (Standard).

Ross - Fixed Cone Valve

PRECISION CONTROL over entire gate opening/elosing stroke through the use of twin ACMH threaded power serews. Signifieanec of this? Able to precisely control and maintain flow at any gate opening/closing position from 1% open to full 100% open.

Extreme Service Valves

Ross - Multi Orifice Valve

The main valve shall be comprised of three main sections, namely the valve body: the fixed plate, and the linear plate. The valve body shall be wafer style, capable of bi-directional flow, and shall be suitable for vertical or horizontal installation. The fixed and linear plates shall be surface ground on the mating surfaces to minimize leakage, and shall incorporate a dielectric link between the discs and the valve body to prevent corrosion. An adjustable tensioning device shall be incorporated into the design to control the corresponding leakage. O-ring packings shall be provided throughout the valve to insure tight seals and true alignment. The design shall be such that replacement of the standard seals in the main valve may be made without its removal from the line.

Pump Control Valves

Ross - Pump Control Valve

The pump control valve shall be globe (inline) or angle (90 degree) body with flanged end connections, be fully mounted, external pilot operated, with free floating piston (operated without springs, diaphragm or levers). It shall contain a single full-ported seat, with seat bore equal to size of valve. The minimum travel of the piston shall be equal to 25% of the diameter of the seat. For true alignment (to correct lateral thrust and stem binding), the piston shall be guided above and below the seat a distance equal to no less than 75% of the diameter of the seat.

Ross - Deep Well Pump Valve

The deep well pump control valve shall be located off a tee connection from the main line in order to blow off air or sand particles agitated by the pump starting. Because the valve is fully open when the pump starts and then slowly closes, it effectively discharges unwanted media from the system before water flows through the main line. In addition, the valve insures a smooth stopping and starting flow in the system by closing slowly after the pump starts and being 95% open before the pump stops.

Metal Seated Ball Valves

Ross - Metal Seated Ball Valves

The AWWA C507 ball valve shall be Metal to Metal Ball Valve (Model MSBV) as manufactured by Ross Valve Manufacturing Co., Inc. It shall be a full-ported valve (Pressure Class 150 -175 psi maximum differential pressure (cast iron) or Pressure Class 250/300 - 350 psi maximum differential pressure (ductile iron)) and shall be complete with valve operating mechanism, valve actuator and accessories as specified herein.

Pressure Reducing

Ross - Pressure Reducing Valve

The pressure reducing valve shall be globe (inline) or angle (90 degree) body with flanged end connections, be fully mounted, external pilot operated, with free floating piston (operated without springs, diaphragm or levers). It shall contain a single full-ported seat, with seat bore equal to size of valve. The minimum travel of the piston shall be equal to 25% of the diameter of the seat. For true alignment (to correct lateral thrust and stem binding), the piston shall be guided above and below the seat a distance equal to no less than 75% of the diameter of the seat.

Ross - Pressure Reducing Valve

The pressure reducing valve shall be globe (inline) body with flanged or female NPT end connections, be fully mounted, external pilot operated, with free floating piston (operated without springs, diaphragm or levers). It shall contain a single full-ported seat, with seat bore equal to size of valve. The minimum travel of the piston shall be equal to 25% of the diameter of the seat. The piston shall be cushioned and so designed as to insure positive closure. The main valve shall be packed with leather (or other soft material) to insure tight closure and prevent metal-to-metal friction and seating. The valve shall be furnished with pet-cocks for attachment to valve body for receiving gauges for testing purposes. The design shall be such that repairs and dismantling internally of main valve may be made without its removal from the line.