Royal Precision Filtration System products

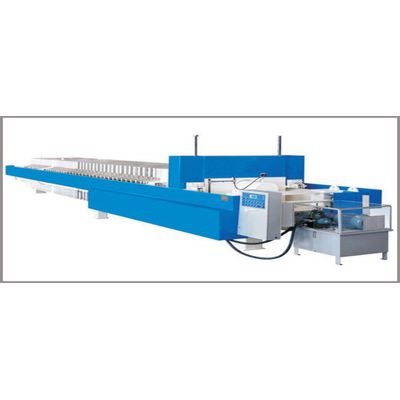

Royal - Recessed Chamber Filter Presses

Chamber Filter Press is the traditional recessed chamber filter press operation employs a steady increase in pressure over time as the cake thickness increases, in order to achieve the optimum combination of chamber filling and cake dryness. At a significantly reduced filtrate rate, the filtration is stopped, the press discharged and a new cycle started. Chamber filter presses are reliable and robust in many different applications. The plate pack consists of uniform chamber plates with a recess of 15 - 50 mm to from the filter cake. A chamber plate is a combination of a filter plate and two half frames in once piece. The standard material for chamber plates is Polypropylene. Possible operating pressures: 7, 15 and to the max of 24 bar (kg/cm2).

Royal - Membrane Filter Presses

Membrane Filter Presses are used for extra Moisture reduction in the cake. It contains one Membrane Plate which has the inflatable elastomer, and a companion plate made of solid Poly propylene. During the initial phase of the filtration, usually called filling cycle, the process is similar to the chamber filter press. After reaching a predefined pressure, usually around 4-7 bar, depending on the sludge characteristics, sludge feeding is stopped and the membranes slowly inflated, using either water or air as squeeze medium. The cake is hereby compressed and dewatered further. This process is continued until the filtrate flow reaches a preset minimum limit. Then the squeeze medium is relieved and the cake discharged.

Royal - Screw Pump

Our organization specializes in manufacturing a qualitative screw pumps .The given Screw pump is available on different specifications in order to meet the need of customers. This Screw pump is manufactured by optimum quality material & advance technology in adherence with set industry standards. Our quality controllers conduct a series of tests on this Screw pump before dispatching to our customers.