RPS Engineering, Inc. products

Waste Water - Flat Tank Covers

RPS - Model F.R.P. 13300 - Flat Panel Cover

This specification is for a fully engineered, substantially airtight, fiberglass reinforced plastic (FRP) cover structure comprised of panels, and beams or trusses as manufactured. This specification shall be regarded as a minimum standard for design and fabrication. Scope of Work: Furnish all labor, materials, and equipment to provide a complete, installed system of easily removable, custom fit, flat FRP covers. The cover system includes cover panels, structural supports, access hatches and attaching hardware.

Waste Water - Fiberglass Domes

RPS - Model FRP - Fiberglass Dome Covers

Shop drawings in accordance with submittal procedures, including: Available colors. Design calculations. Dimensional drawings showing anchor locations and location and size of all openings.

Waste Water - Launder & Channel Covers

RPS - Aluminum Launder Covers

Provide Aluminum Channel Cover and all accessories as specified herein and on the contract drawings.

Conveyor Covers

RPS - Model CH Series - Conveyor Cover

RPS Engineering’s CH-Series hood assemblies are full 180° coverage and are hinged so they can be quickly and easily opened for inspecting or viewing the items being conveyed. They also allow for ease of repairing, replacing, greasing or inspecting of the idlers. Conveyor hoods help to protect the belt, idlers and material being conveyed from the hot sun, wind, snow, rain and other damaging weather elements.

RPS - Model CH-75 Series - Conveyor Cover

RPS Engineering’s CH75-Series hood assembly is ¾, 135° coverage with a 45° degree opening. This series is stationary. They help to protect the belt, idlers and material being conveyed from the hot sun, wind, snow, rain and other damaging weather elements, but still allow one to view the belt and items conveyed without having to touch the covers.

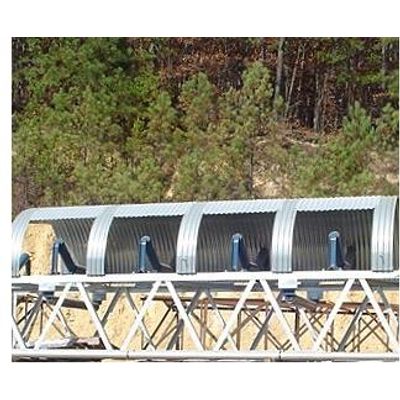

RPS - Model CHCO Series - Conveyor Cover

RPS Engineering’s CHCO-Series hood assembly is full corrugated cover and band with a 180° coverage. Because these are corrugated, these are more rigid and made from a heavier gauge material than our standard CH smooth series. They are quick opening and hinged for inspecting or viewing the items being conveyed. They also allow for ease of repairing, replacing, greasing or inspecting of the idlers. They help to protect the belt, idlers and material being conveyed from the hot sun, wind, snow, rain and other damaging weather elements.

RPS - Model CHLC Series - Conveyor Cover

RPS Engineering’s CHLC-Series hood assembly is a ¾ corrugated cover and band with a 135° coverage. Because the corrugations are parallel with the belt, these are a more economical cover system. They are stationary with a standard 45° opening. This allows for inspecting or viewing the items being conveyed and the ease of repairing, replacing, greasing or inspecting of the idlers without touching the cover assemblies. They help to protect the belt, idlers and material being conveyed from the hot sun, wind, snow, rain and other damaging weather elements.

RPS - Model CHCS Series - Conveyor Cover

RPS Engineering’s CHCS-Series hood assembly is a ¾ corrugated cover and band with a 135° coverage. Because these are corrugated, these are more rigid and made from a heavier material than our standard CH smooth series. They are stationary with a standard 45° opening. This allows for inspecting or viewing the items being conveyed and the ease of repairing, replacing, greasing or inspecting of the idlers without touching the cover assemblies. They help to protect the belt, idlers and material being conveyed from the hot sun, wind, snow, rain and other damaging weather elements.

RPS - Model CHFG Series - Conveyor Cover

RPS Engineering’s CHFG-Series hood assembly has a full 180° coverage. These are great for a more corrosive atmosphere and are often used in the salt and fertilizer industries.