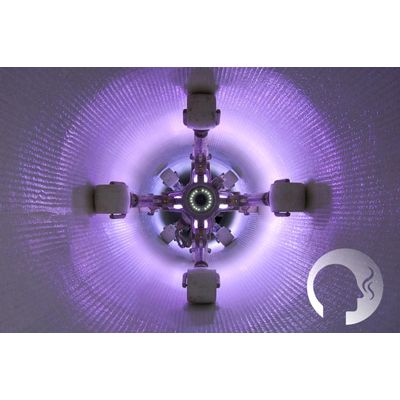

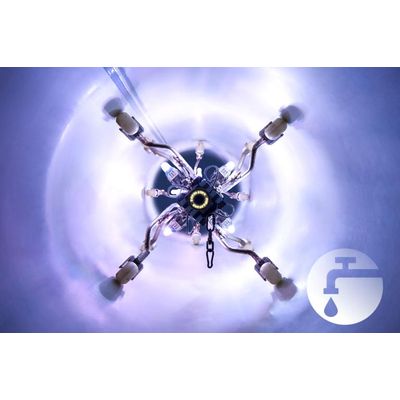

Pressure-resistant, hygienic, award-winning: SAERTEX-LINER® H₂O offers superior mechanical characteristics for the trenchless rehabilitation of potable water supply lines using the UV-CIPP process. Our UV-cured GRP pipe liner is approved in over 14 countries and won the ISTT Innovation Award in 2019. It is available in two design options: Type S+: low-cost alternative for low operating pressures up to 1 bar. Type S+ XR: suitable for potable water supply lines at pressures up to 33 bar

SAERTEX MultiCom GmbH

5 products found