- Home

- Companies

- Sahara Industry

- Products

Sahara Industry products

Water Treatment Systems

Sahara - Reverse Osmosis Plants

Reverse osmosis is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied.

Sahara - Ultra Pure Systems

Sahara Industry is an expert in providing standardized and customized UPW plants which supply a high form of purified water with resistivity or conductivity up to (

Membrane Housing

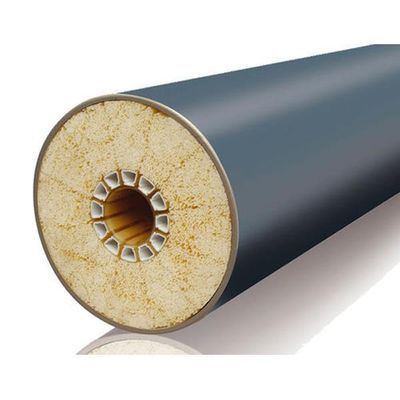

Sahara - Membrane Housing

Sahara Industry produces the finest FRP Membrane Housing that are designed to handle the highest pressure required by membranes today during treatment operations. These pressure vessels are coated with highly durable fiberglass and incorporate end caps for longer life usage in the face of corrosive conditions.

Sahara - Membrane Housing

Sahara Industry has over 20 years of experience as a global provider of top-quality membrane pressure vessels that are specifically designed to allow RO membranes to withstand high pressure water treatment applications. These pressure vessels are reinforced in fiberglass housings, which greatly increase the strength and durability of the membranes.

Pressure Vessel

Sahara - Pressure Vessels

Sahara Industry provides exceptionally easy to operate, user-friendly, and low expense FRP Pressure Vessels / FRP Filter Tanks to various applications across the world. Our objective is to deliver safer, cleaner, and healthier water through the removal of biologically harmful contaminants.

Sahara - Smooth / Glossy Finishing Pressure Vessels

SAHARA INDUSTRY offers a wide range of FRP Composite pressure vessels for the Water and desalination industry Our DROPLET range of Composite pressure vessels are manufactured on highly sophisticated CNC controlled automatic machines promising same repeatability and precision quality over wide range of models. DROPLET vessels are manufactured in LDPE as well as FRP liner option. DROPLET LDPE liner vessels are standard vessels made up of virgin quality natural color LDPE material which ensures no algae formation in longer usage.

Multiport Valve

Sahara - Manual Multiport Valve

We offer clients a vast range of multiport valves(MPV) which are used for small and medium-size water treatment plants. Multiport valves are made from wear-resistant high hardness ceramics that provide longer service life. Innovatively designed, easy to handle, they also provide excellent seal capability preventing internal leakage. By just clockwise and anticlockwise rotating of the handle, multiple functions can be performed such as filter backwash, rinse brine suction, and brine rinse.

Sahara - Automatic Multiport Valve for Water Softener

Traditional manual multi-port valves can be replaced by automatic ones. A simple adjustment to the settings using the remote control or keyboard, depending on the model, enables the system to automatically control the operation of a sand Filter / Activated Carbon Filter / Pre Treatment, thus saving users time and effort. Automatic multi-port valves can carry out the same processes as manual ones, but in a totally automated way once they have been programmed. Some valves come with a remote control and others with a keyboard.

Membranes

Sahara - Reverse Osmosis (RO) Membranes

Sahara Industry provide wide range reverse osmosis membranes for your systems and installations from the most leading membrane producers/ Our service includes selection, logistic and delivery to your stock/site under request. We ensure prompt deliveries directly from producers stocks and or workshops depending on requested quantities within shortest time of delivery directly to your stock/installation site or client.

Sahara - Ultra Filtration (UF) Membrane

Ultrafiltration (UF) is a separation process using membranes with pore sizes in the range of 0.1 to 0.001 micron. Typically, UF membranes will remove high molecular-weight substances, colloidal materials, and organic and inorganic polymeric molecules. Low molecular-weight organics and ions such as sodium, calcium, magnesium chloride, and sulfate are not removed by Ultrafiltration Membranes (UF Membranes). Because only high-molecular weight species are removed, the osmotic pressure differential across the UF Membrane surface is negligible. Low applied pressures are therefore sufficient to achieve high flux rates from an Ultrafiltration membrane. Flux of a membrane is defined as the amount of permeate produced per unit area of membrane surface per unit time. Generally flux is expressed as gallons per square foot per day (GFD) or as cubic meters per square meters per day.