- Home

- Companies

- Sahut-Conreur

- Products

Sahut-Conreur products

Laboratory Equipments

Pharma Compactor

The PHARMA compactors improve and simplify the dry process granulation for a fair number of applications. It is particularly true when some powders have to be densified or when their compactability or flowability needs improving. This compactor also enables to stabilize mixtures of powders and ensures an easier packaging, handling, storage and/or transport of powders.

Briquetting

Sahut-Conreur - Briquetting Process Units

Briquetting units transform fine materials, whether cold or hot (i.e. from -40°C up to + 1000°C) in various shapes, sizes and volumes (from a few cc to 600 cc and more). These characteristics are defined according to the product end use. The briquetting process allows to reduce the volume of the powder by its densification to reach briquettes with a true density of about 5g/cm3.

Sahut-Conreur - Cold Briquetting Press

Sahut-Conreur - Cold Briquetting Sponge Iron

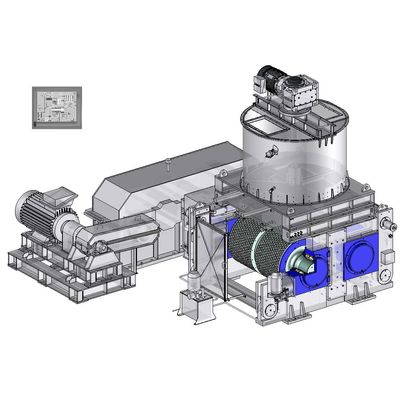

Sahut-Conreur - Integrated System

SAHUT-CONREUR provides compact and complete turnkey systems (including electrical interlocking and interfacing control) integrating other equipment around the briquetting press. These briquetting units are built to meet specific needs (space available,…)

Sahut-Conreur - Hot Briquetting Iron (HBI)

Briquetting - Mixing Equipment

Sahut-Conreur - Pugmills

Sahut-Conreur - Twin Screw Mixers

SAHUT-CONREUR has developed its own range of twin screw mixers specially adapted for spraying water or liquid agent. These twin screw mixers are implanted in steel-making, chemicals and minerals plants for heavy-duty operation under hard and difficult conditions. Our twin screw mixers cover a large capacity range from 500 Kg/hr up to 50 T/hr.

Sahut-Conreur - High Speed Mixers

SAHUT-CONREUR has developed its own range of high speed mixers specially adapted for spraying water or liquid agent. These high speed mixers are implanted in chemicals and minerals plants for continuous operation. Our high speed mixers cover a large capacity range from 50 Kg/hr up to 5 T/hr.

Compaction-Granulation

Sahut-Conreur - Compaction-Granulation Process System

Compaction-granulation is a dry process that transforms powders into randomly shaped granules in a calibrated range (e.g. 0.2 to 0.8 mm, 0.4 to 1.2 mm, 2 to 4 mm, etc....). Usually no binder is required in this process and the bonding of the particles is only ensured by the mechanical pressure applied to the product to be compacted. The raw material is compacted, at low, medium or high pressure (depending on the properties of the raw material), in the form of flakes of variable thickness (up to 30 mm). The capacity of a compaction-granulation unit can range from 50 kg/h to 50 T/h of granules and for products with a temperature up to 200°C, and over.