- Eddy Current Inspection Equipment - Turnkey Stand Alone NDT Inspection Systems

- Eddy Current Inspection Equipment - Robotic Eddy Current Test Systems

- Eddy Current Inspection Equipment - Gantry Systems & Testing Platforms with XY and XYZ Gantry Robots

- Hardness Testing Systems & Machines - Hardness Testing Systems & Machines

- Hardness Testing Systems & Machines - Rockwell HRC Testing & Evaluation Machines

- Gauging Solutions for Dimensional Measurement Inspections

Salem Design & Manufacturing, LLC products

Eddy Current Inspection Equipment - Turnkey Stand Alone NDT Inspection Systems

Salem - Gear Blank Testing Machine

Pre-production inspection for fabricated parts and blanks using eddy current inspection probes

Eddy Current Inspection Equipment - Robotic Eddy Current Test Systems

Salem - Pre-production Wheel Bearing Inspection Machine

Eddy Current inspection system for wheel bearing, housing, and spindles in the automotive & aerospace industries.

Eddy Current Inspection Equipment - Gantry Systems & Testing Platforms with XY and XYZ Gantry Robots

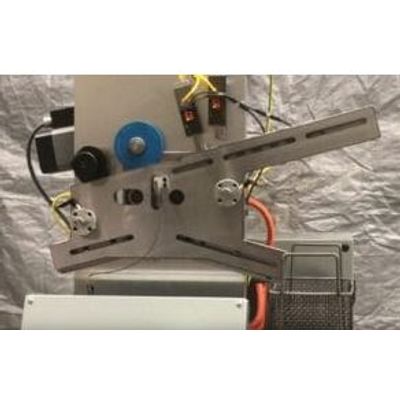

Salem - Eddy Current Transmission Shaft Testing Machine

The transmission shaft inspection machine is built using the Uni-Versal Eddy Current inspection system. This machine can test a transmission shaft for flaws or defects. Combing the power of a FANUC LR Mate 200iD Robot and a Criterion NDT eddy current testing instrument, manufacturing operations have the advantage to test materials in small spaces. Pre-production transmission shaft inspection system for the automotive & aerospace industries.

Hardness Testing Systems & Machines - Hardness Testing Systems & Machines

Salem - Pre-Production Transmission Clutch Plate Testing Machine

The transmission clutch inspection system is a pre-production non-destructive testing process used by industries worldwide to inspect manufactured components before going into final production. Using a cnc eddy current system combined with a laser inspection, the eddy current testing system provides instant verification allowing manufacturers to detect flaws or defects in the metal as well as capture the complex internal geometry of parts without needing visual access or destroying the part. Eddy current component inspection system for the automotive & aerospace industries.

Salem - Disc Brake Eddy Current Rotor Inspection System

Pre-production brake component inspection system for the automotive & aerospace industries. Porosity in die casting brake rotors is found when there are small voids, holes, or pockets of air found within the metal. The dual spindle machine inspects each individual rotor for porosity. It has a fast 30 second part to part cycle time. Not to be confused with eddy current brakes or magnetic braking technology, this machine uses eddy current sensors that inspect the metal alloys for any cracks or flaws.

Hardness Testing Systems & Machines - Rockwell HRC Testing & Evaluation Machines

Rockwell - Testing & Evaluation Machines

The Rockwell HRC hardness test is a non-destructive testing method performed on the production floor to check the strength or hardness of metallic materials. The machine is equipped with a penetrating tip that instantly checks the material’s resistance without making a permanent indentation. The Rockewll HRC hardness testing method uses a diamond penetrator which allows for a higher accuracy measurement.

Gauging Solutions for Dimensional Measurement Inspections

Salem-Republic - Brake Shoe Bench Gauge

Brake shoes are manufactured in a variety of diameters according to the specifications required by the application. Inspection occurs early on in the manufacturing process of brake shoes to reduce costs and increase safety. While much of the brake shoe inspection process is automated in today’s manufacturing environment, there are still some custom applications that may require manual gauge checks that can measure the geometry of a variety of brake shoes. Contact Salem Design and Manufacturing today to discuss your needs for inspecting.

Salem - Truck Axle Shaft Gauge Bench Test System

Obtaining an accurate measurement of your manufactured axle shafts is easy with one of our truck rear axle gauging systems. Equipped with a gauge that provides compensation feedback, this machine is capable of being robot-loaded and can quickly measure the flange diameter, thickness, overall length, spline diameter, and journal diameter of a variety of different parts.

Salem - Transmission Shaft Double Gauging System

Industry’s standards for OD & Taper measurements for transmission shafts. This dimensional gauge measures the diameter of shafts in two places to verify OD and taper. Feedback is provided to compensate the production machine. The machine adjusts to handle different length shafts.

Salem - Double Gauge & Measurement System for Braking Systems

Automatic gauging machine for measuring and inspecting S-camshafts.