- Home

- Companies

- Scheuch Ligno GmbH

- Products

Scheuch Ligno GmbH products

Extraction Technology

Scheuch-Ligno - Excess Pressure Systems

Scheuch-Ligno - Negative Pressure System

The sepas+ chip extraction system offers a performance range of 9,000 m³/h and above, and its highly efficient use of energy makes it an outstanding choice. The sepas+ system enables the extraction output to be adapted to the fluctuating machine capacity and is therefore particularly energy-efficient.

Metal Extraction Technology

Scheuch Ligno - Welding Fume Extraction System

Effective welding fume extraction is highly important to guarantee health and well-being of employees in the metal-based industry. When welding, the high heat input in the material releases gases and vapours that are often smaller than 1 µm and therefore penetrate deep into the lungs. Professional welding fume extraction from Scheuch LIGNO removes these harmful particles and hazardous materials from the production hall and ensures that the legal limit values are complied with.

Filter Technology

Scheuch Ligno - Deduster

The Scheuch LIGNO DeDust PRO series is designed in accordance with DIN EN 16770. These dedusters can be used for flow rates of up to 10,000 m³/h. They are devices used to extract wood dust and chips from wood processing machines. The deduster may only be installed indoors. However, this provides significant advantages over stationary filter systems. The DeDust PRO is delivered fully-pre assembled and wired. Setup indoors is also possible without explosion protection measures. The DeDust PRO therefore saves you money. Scheuch LIGNO dedusters extinguish fires by removing oxygen and not using a fire extinguisher. The high-cost inspections of special triggering equipment and the fire extinguisher are therefore not required for the machine’s entire service life.

Surface Technology - Pre-Treatment

Scheuch Ligno - Grinding Booth

The Scheuch LIGNO grinding booths can be used in modules. This individual module design enables booth sizes to be adapted to the customers’ wishes.

Scheuch Ligno - Overhead Grinding Booth

Overhead grinding booths are ideal as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines.

Scheuch Ligno - Underfloor Grinding Booth

On underfloor grinding booths, extraction takes place via a floor pit. They are used as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines. Furthermore, they reduce dust and noise.

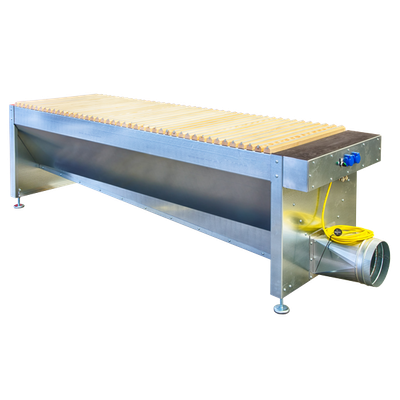

Scheuch Ligno - Grinding Tables

Grinding tables are used as additional extraction units to go alongside the device’s own extraction function for manual grinding work with hand-held grinders and for work with manually operated grinding machines. The grinding table reduces dust considerably. If the grinding table has a work surface which can be pivoted infinitely, this will make it even more functional and ergonomic. The ability to adapt the workpiece inclination to the grinding processes in question (surface, transverse edges or longitudinal edges) makes the grinding work much easier. Pressing a button releases the pneumatic lock and the grating can be swung into the position required for processing manually.

Scheuch Ligno - Blasting Cabins

Scheuch LIGNO provides blasting rooms and blasting booths that are adapted to the customer’s requirements. The materials are conveyed via conveyor floors driven by pneumatic cylinders. The booth designs with heavy goods vehicles for material transport or tracks to enable forklifts to move are adapted to the customer’s requirements. The blasting agent reprocessing and recovery are fully automated. The filter technology and the extraction systems are state of the art in order to protect employees and the environment. The blasting room designs can be configured individually – with a ceiling slot to use the hall crane for filling or to enable access by forklifts. Hoists to handle the components to be blasted can also be integrated.

Conveying Technology

Scheuch - Low Pressure Conveying Systems

The material is transported using a closed circular pipeline conveyor system. The radial fan blows the separated material in the conveyor pipe towards the material separator. The recycled air is fed back towards the radial fan. With this type of conveyance, the air is guided in a circular motion, which means that no dust is discharged.