Sebigas Renewable Energy srl products

Sebigas - Continuous Flow Stirred Tank Reactor

The CSTR (Continuous-Flow Stirred Tank Reactor) is a technological solution that requires a continuous flow of fresh biomass. The biomass fed into the reactor is constantly mixed to ensure a perfect homogenization. In the CSTR, the anaerobic digestion process takes place at controlled temperatures and for dry matter contents below 10 percent. The retention time is variable and depends on the types of biomasses used to feed the plant.

Sebigas - Anaerobic Moving Bed Bio Film Reactor

The anMBBR (Moving Bed Bio Film Reactor) is a technological solution that enables the treatment of industrial wastewater in anaerobic digestion. The biomass used as the plant feeding is characterized by a low or no dry matter content, or highly diluted wastewater. With the anMBBR reactor, biomass with very high energy potential can be enhanced. It therefore turns out to be an alternative to traditional treatments, which tend to be very energy-intensive, but essential for the proper management of biomass in the production chain. With retention time of less than 10 days, digestion takes place in variable thermal regime, psychrophilic or mesophilic.

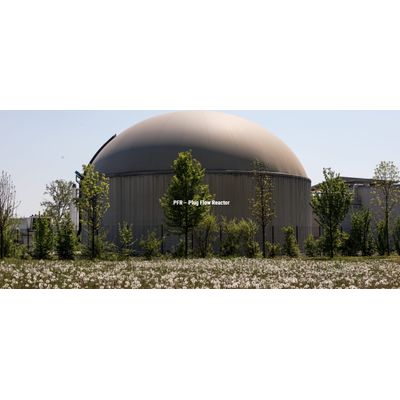

Sebigas - Plug Flow Reactor

The plug-flow reactor (PFR) is suitable for the treatment of biomass with high dry matter content. The reactor is not equipped with a continuous mixing system, but with an equipment made up of paddles or screws. They allow to move the biomass through the reactor and let the biogas move upwards into the heated environment before being collected and treated. This reactor can be coupled with several upstream and downstream systems properly designed to treat the raw biomass or the digestate produced by the process.

Sebigas - Covered Lagoon Reactor

The Covered Lagoon Reactor (CLR) is a technology that enables the anaerobic digestion of high volumes of liquid wastewater. Characterised by a very low dry matter content and a low fibre content, the process takes place by recirculating the biomass within a lagoon at controlled temperature and flow rates, in an activated sludge layer. With variable retention times, anaerobic digestion takes place in a psychrophilic or mesophilic thermal regime, depending on the biomasses entering the reactor.