Sep-Pro Systems, Inc. products

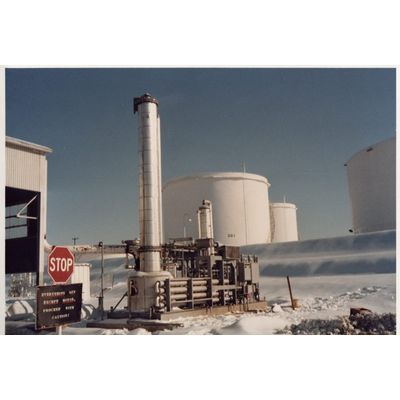

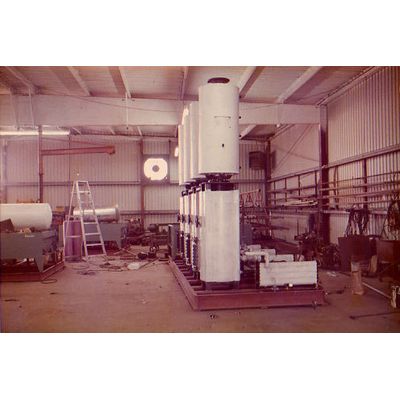

Sep-Pro - Acid Gas Removal Systems

Acid Gas Removal systems involve removal of inert gasses such as carbon dioxide, hydrogen sulfide, and nitrogen from unprocessed natural gas. These must be removed prior to use or sale of the natural gas to meet standards of less than 4% inert gases. Acid gases such as carbon dioxide (CO2) and hydrogen sulfide (H2S) are corrosive when water molecules are present and represent the major source of maintenance problems in pipelines. Acid gas removal plants are essential to natural gas processing and transportation and are one of the major parts of natural gas processing equipment manufactured.

Sep-Pro - Adsorption Systems for Chemical Engineering

Adsorption is one of the major chemical engineering unit operations, primarily used as an alternative to distillation when the substances involved do not have a significant difference in boiling points. When a specification requires low ppm concentration in the product, adsorption is usually appropriate.

Sep-Pro - Air Coolers

Sep-Pro Systems designs and manufactures process air coolers that are usually custom-designed. Some of our custom-designed features include:

Sep-Pro - Ammonia Absorption Refrigeration System

Ammonia absorption refrigeration is time-tested technology that has come of age. Waste heat recovery can be combined with absorption chilling to reduce or eliminate the electric power bill of mechanical refrigeration. For instance, if a company has a power-generating gas turbine, the high temperature exhaust heat can be converted to refrigeration with an ammonia absorption refrigeration (AAR) process.

Sep-Pro - Biomass Processing System

Biomass processing is an efficient way of producing energy from non-fossil fuel resources. Other renewable energy approaches untilize wind, solar, geothermal, and hydropower to produce energy. Unlike other renewable energy sources, biomass can be directly converted into liquid fuels including ethanol, biodiesel, and other hydrocarbon fuels. Algae, sawdust, waste manure, trap grease, landfill gasses, and even scrap automobile tires can serve as an abundant, high-yield, and very profitable source of energy.

Sep-Pro - Crude Oil Topping Units

Crude oil distillation using crude oil topping units fills a need for oil producers that have domestic requirements for diesel, fuel oil, kerosene, AGO, LPG or asphalt but don’t have total refining capacity. Essentially they are atmospheric distillation units that produce hydrocarbon boiling point cuts from resid to LPG. A topping unit is an inexpensive, technically simple means to enhance the value of crude oil near the source of production.

Sep-Pro - Desalination Units

Sep-Pro Systems designs and manufactures two types of oil desalination units.

Sep-Pro - Gas to Liquids Technology for Gas Recovery

Gas To Liquids (GTL) Plants are being used to meet the increasing interest in reclaiming stranded natural gas around the world. GTL technology is quickly evolving as an economic means to add value to gas that otherwise has limited worth and utility. GTL solves stranded gas problems by converting the gaseous material to synthetic hydrocarbon liquids that can be transported and sold more easily and cost-effectively.