- Home

- Companies

- SEPARATECH

- Products

SEPARATECH products

Centrifuge Parts OEM

SEPARATECH - OEM Bowl Parts of Decanter Centrifuge

Reliability, quality, and performance are the reasons you invested in a oem bowl parts of decanter centrifuge in the first place. Protect your investment, and maintain decanter centrifuge performance by trusting SEPARATECH Certified Service for ongoing maintenance, emergency service, OEM quality parts, and other repairs. For a decanter centrifuge, the bowl is the most critical part besides the scroll. The bowl of decanter centrifuge mainly consists of a large end hub, a cylindrical section, a conical section, and a small end hub. The conical section has one (or two) row(s) of solids discharge openings. The discharge openings are in most cases lined with replaceable bushings or liners made from abrasion resistant material such as stellite or tungsten carbide material. The large end hub has four or more liquid discharge openings.

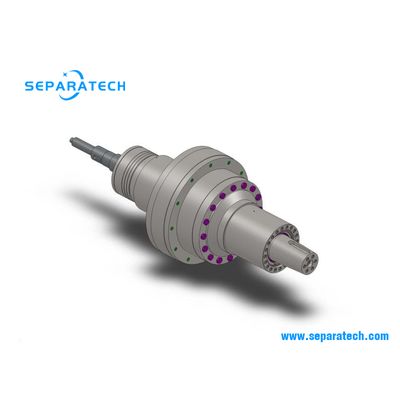

SEPARATECH - Scroll Conveyor of Decanter Centrifuge

SEPARATECH provides OEM scroll conveyor of decanter centrifuge, reverse engineer and optimize all decanter centrifuges for any decanter centrifuge brand. Our experience makes all the difference for accurate and durable scroll conveyor of decanter centrifuge manufacturing. The scroll conveyor, conveyor screw, is in the form of an Archimedean screw. fitting inside the beach and bowl between the two end hubs. with a small clearance of less than 2 mm radially. It has a number of functions. Not only does it convey the solids, after they form a cake. along the cylindrical bowl section and up the beach, it also accepts the feed and accelerates it up to bowl speed.

SEPARATECH - Decanter Centrifuge Gearbox

The planetary gearbox system consists of a pinion shaft and gear, which engages three planetary gears (mounted on carrier plates) which in turn engage a ring gear fixed to the gearbox casing. For the decanter centrifuge the epicyclic gearbox involves two stages. although recently three stages have been in use. The carrier plate of the first stage holds a second pinion shaft carrying the sun gear for the second stage. The ratio of the decanter centrifuge gearbox is the product of the ratios for each stage. The maximum practical ratio for any stage is just over 1 3. giving a maximum ratio for a two-stage planetary gearbox of 170 to 180. Three stage epicyclic gearboxes with ratios over 500 have been used on decanters.

SEPARATECH - Alfa Laval Purifier Parts OEM

Alfa Laval purifier parts from SEPARATECH varying from aftermarket replacement separator spare parts to service kits.Our supplied parts give you a true cost-efficient peace of mind. Whether you are looking for aftermarket replacement parts or genuine OEM Alfa Laval disc separator spare parts and/or accessories, we are your best choice.

SEPARATECH - Customized Discs for Disc Centrifuge

Customized discs from SEPARATECH for all brands of high-speed disc stack centrifuges. Disc stack plays a critical role in the bowl during centrifugation.The disc is one of criticle parts of disc stack centrifuge, disc quality, such as machining accuracy, surface roughness, etc., affects the centrifugal separation effect directly. SEPARATECH team has a deep understanding of discs and the key control points in their production, thanks to decades of experience.